Introduction

This is a how-to guide for replacement of 1-18976 Hyplex Prime Major Repair Kit from Accustream.

-

-

Refer to original equipment manufacturer's safety and maintenance instructions. Failure to do so could result in injury or death.

-

Always remove all stored energy and lock out equipment before beginning any work.

-

-

-

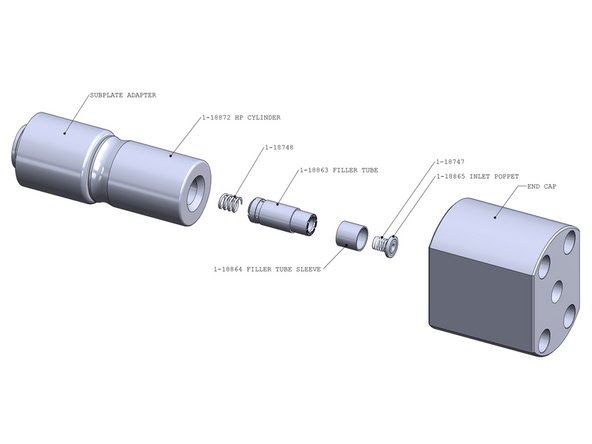

Exploded view with BOM

-

-

-

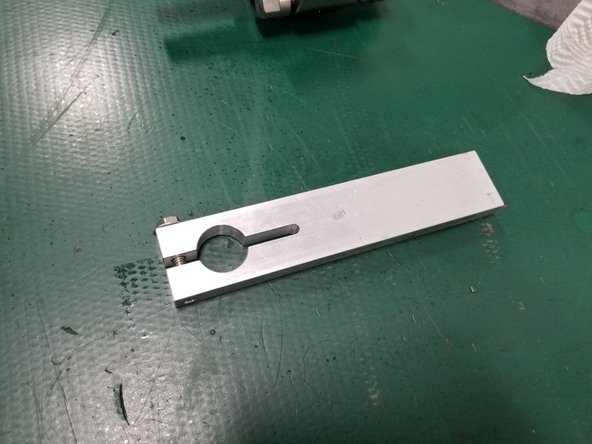

Pressure Loading tool

-

Check valve clamp tool

-

Plunger removal socket

-

-

-

Remove inlet water hoses from the bottom of the end cap

-

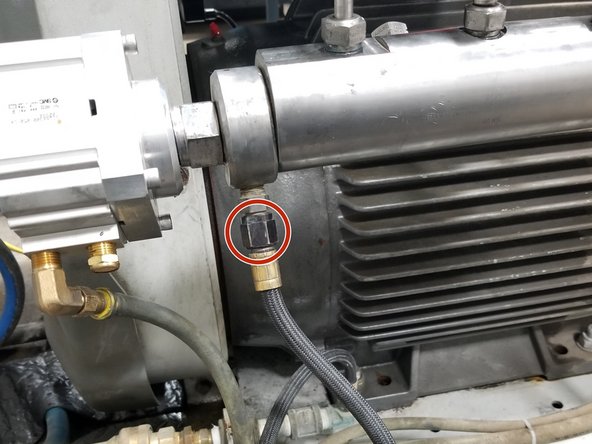

Disconnect air line from actuator

-

Disconnect PCV drain line

-

-

-

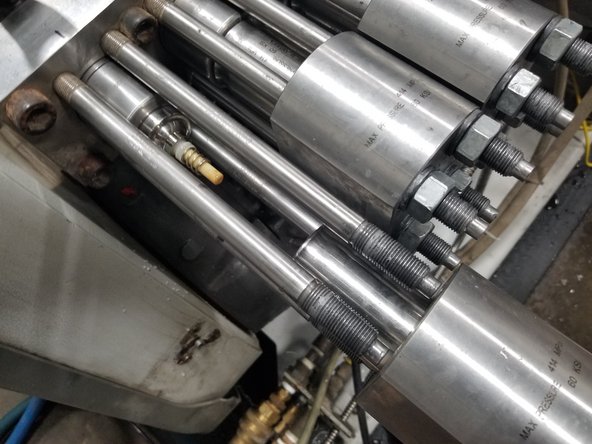

Remove high-pressure tube from manifold using a 13/16" open end wrench

-

Remove high-pressure inlets from all end caps using 13/16" open end wrench while supporting the manifold

-

-

-

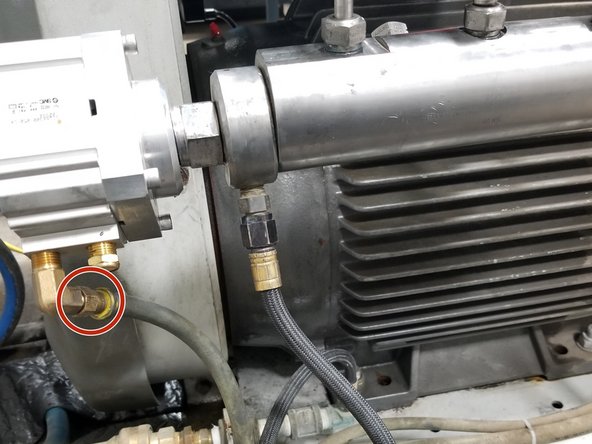

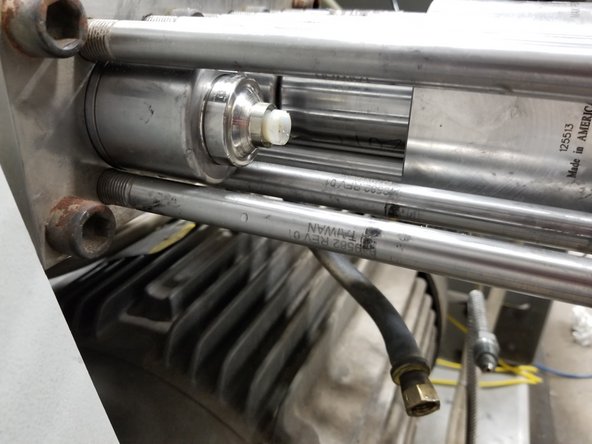

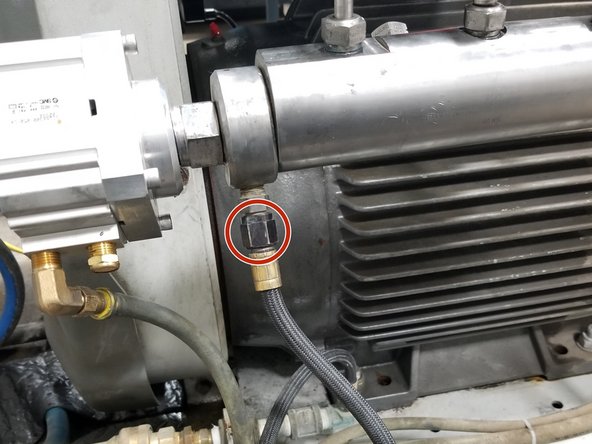

Ensure oil is full. Open the 3/16" hex screw located on the contact face to check/fill using ATF fluid

-

Ensure pressure loading tool screw is fully retracted

-

Ensure piston is fully retracted

-

-

-

Keep screw lubricated with MOLYKOTE® BR-2 Plus or similar

-

Wipe stud threads clean and apply Loctite 8150 anti-seize (#1-18750)

-

-

-

Attach pressure loading tool to each set of studs, rotating each tool stud by hand until tight

-

Once snug, back out the tool studs 1/4 turn. Place a radial line with a permanent marker to make this easier to see

-

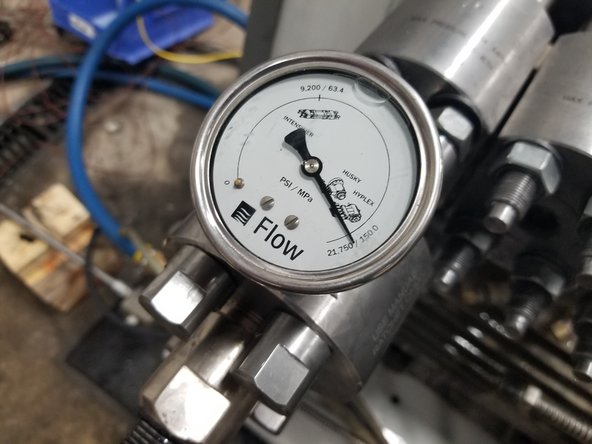

Use a 3/4" (19mm) ratcheting socket to pressurize the tool by rotating screw clockwise. Pressurize per manufacturers recommended gauge pressure

-

-

-

While tool is pressurized, loosen the four nuts a few turns by hand

-

Turn the 3/4" socket counter-clockwise to reduce the pressure in the tool

-

Back off each of the four tool studs and remove the pressure loading tool

-

-

-

Remove the fours nuts and washers

-

Carefully slide the end cap off, being careful not to lose any of the high-pressure components

-

-

-

HP cylinder and filler tube may come out with end cap

-

Use a screwdriver to remove seal carrier, if necessary

-

-

-

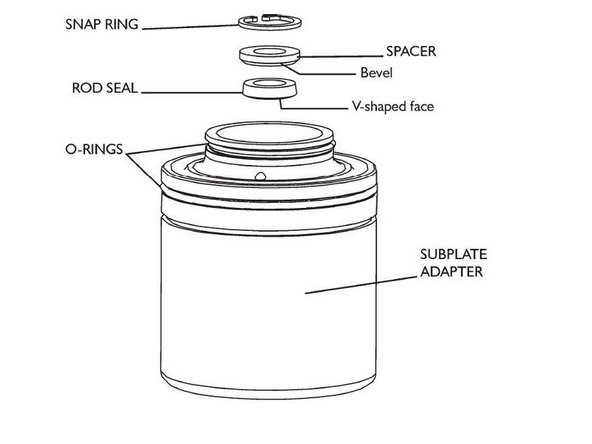

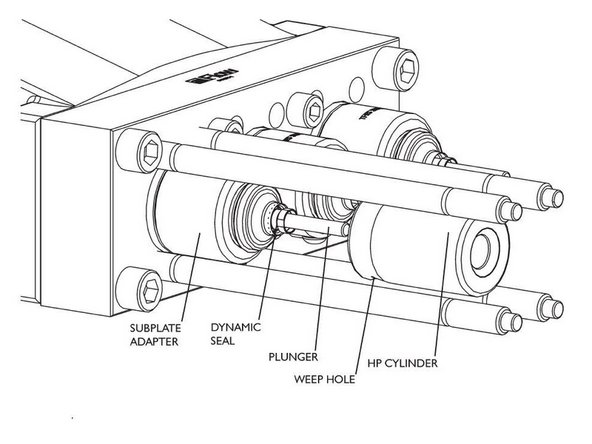

Remove subplate adapter (gently pry groove if necessary)

-

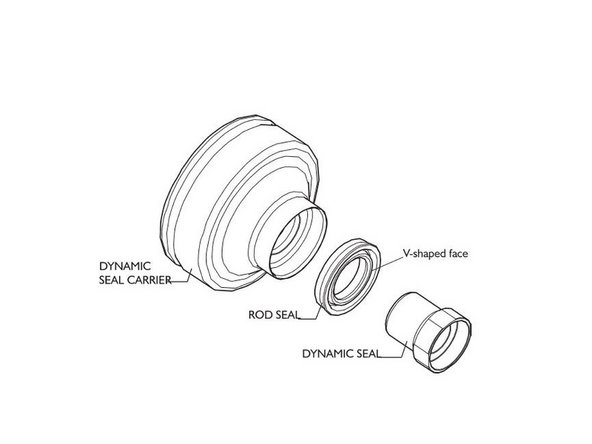

Remove snap ring and rod seal, install new rod seal (1-11993) and snap ring (1-18745). Inspect and replace spacer with bevel down

-

-

-

Use plunger removal socket and ratchet to remove the plunger retaining nut

-

Rotate belt/crank to extend plunger, if necessary

-

Replace with new plunger and spring. Torque plunger nut to 20 ft-lb (27 N-m).Be careful not to contact the plunger

-

-

-

Carefully lift the check valve assembly using two flathead screwdrivers in the groove on the check valve body

-

-

-

Insert check valve body clamp tool into bench vise

-

Use a 9/16" socket to tighten the clamp onto the check valve body

-

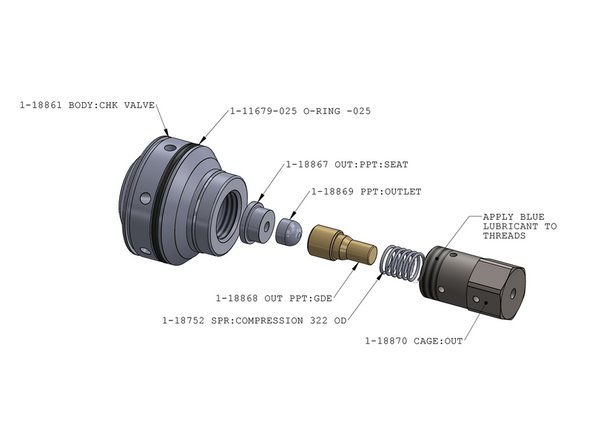

Remove the Outlet Cage using the 9/16" socket

-

Inspect outlet cage. Replace all other items

-

Re-install outlet cage:

-

Apply blue lubricant to outlet cage threads and insert new internal components

-

Carefully thread cage into check valve while maintaining alignment of internal components

-

Torque outlet cage to 30 ft-lb (41 N-m)

-

-

-

Install new End Cap o-ring

-

Apply high-vac grease (1-11447) to both o-rings

-

Insert check valve assembly into end cap

-

-

-

With manifold removed from pump, place manifold in a heavy bench vise

-

Remove the PCV body using a 1-1/4" (32 mm) wrench

-

-

-

Apply blue lubricant to threads and both faces of the PCV adapter

-

Install new PCV Ring onto new PCV Seat, and insert PCV Poppet into seat. Insert PCV assembly into PCV body

-

Thread manifold onto PCV Adapter. Torque to 190 ft-lb (258 N-m)

-

-

-

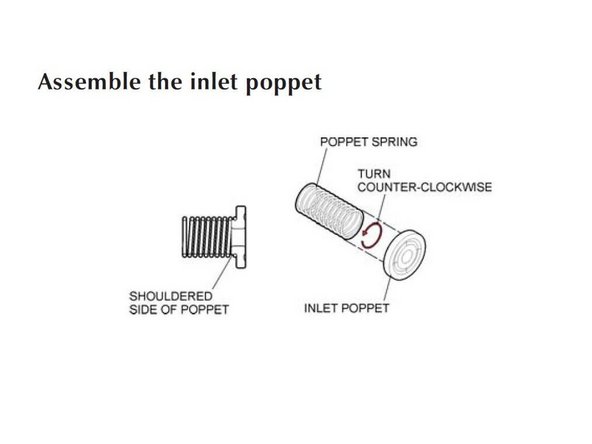

Attach 1-18747 spring to 1-18865 Inlet Poppet

-

-

-

Insert dynamic seal and rod seal into new seal carrier (slight pressure is required to seat dynamic seal)

-

Install rebuilt subplate adapter

-

Slide seal assembly over plunger up to subplate adapter

-

-

-

Insert new o-ring into HP Cylinder. Apply a small amount of high-vac grease to o-ring

-

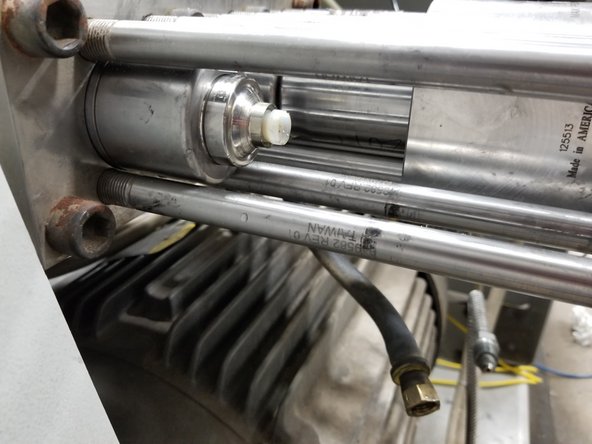

Carefully slide HP cylinder over the seal carrier, keeping the weep hole facing down

-

Insert 1-18748 spring into Filler Tube. Slide filler tube sleeve onto filler tube, insert poppet assembly into filler tube

-

Insert assembly into HP Cylinder

-

-

-

Slide End Cap onto tie rods and align with HP Cylinder

-

Place washers and nuts on tie rods, hand tighten until snug

-

Attach and pressurize the pressure loading tool. Tighten nuts by hand until they are snug against the end cap

-

Remove pressure from pressure loading tool

-

Repeat for all three lines

-

-

-

Apply blue lubricant to high-pressure fittings

-

Torque high-pressure glands to: 40 ft-lbs (54 N-m)

-

Attach manifold/high-pressure glands, air line, PCV drain line, and inlet lines

-

-

-

-

When complete, unlock system and restore energy

-

Start pump and check for any leaks

-