Introduction

Hypertherm is in no way affiliated with the above mentioned manufacturer.

-

-

Always make sure all high-pressure water has been removed from the valve by following the machine manufacturers' safety instructions. Failure to do so can cause severe injury or death.

-

Turn OFF all water pressure to the on/off valve.

-

Turn the on/off valve ON to raise the needle from the seat.

-

-

-

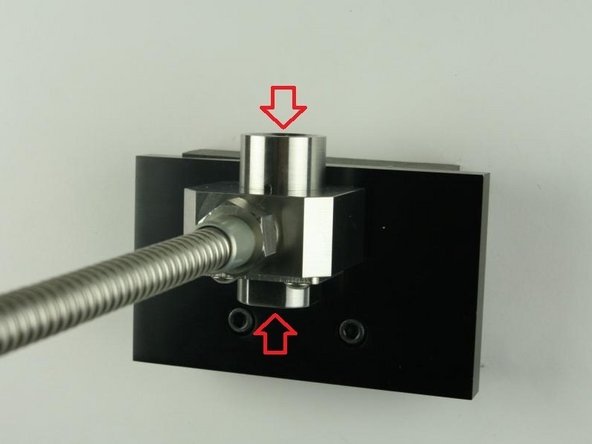

The components can be replaced with the valve body in the mounting collar.

-

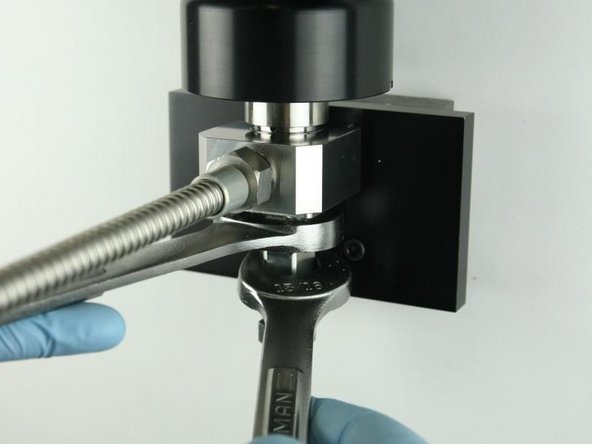

Loosen the adapter from the valve body using a 1" and 13/16" wrench.

-

Unthread the adapter from the valve body.

-

-

-

For similar disassembly see Step 3 kit #13683 (parts/tools may vary)

-

-

-

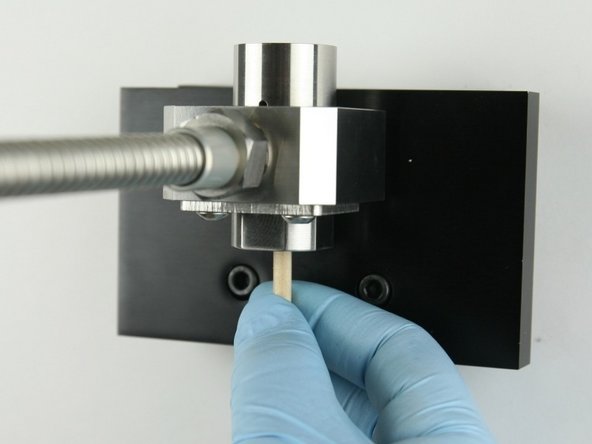

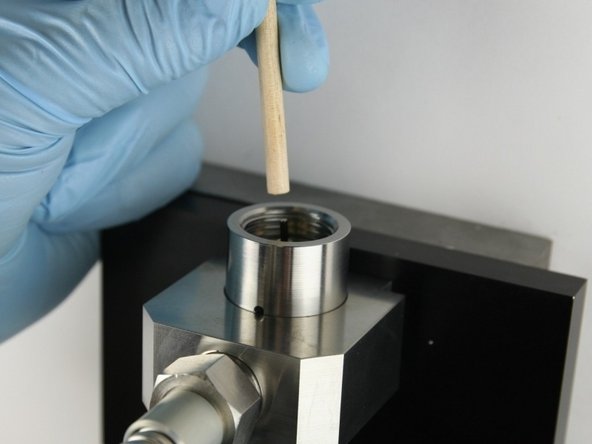

Remove all the valve components using the included dowel.

-

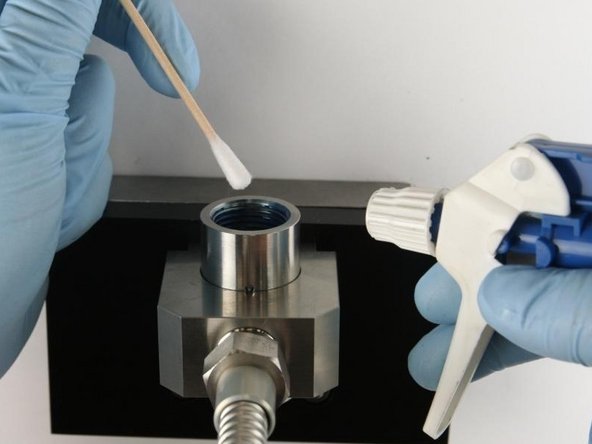

Thoroughly clean the interior/exterior of the valve body with isopropyl alcohol before replacing the components.

-

Put the top and bottom of the bore for cracks/blemishes. If excessive wear or cracks are visible, replace the valve body.

-

-

-

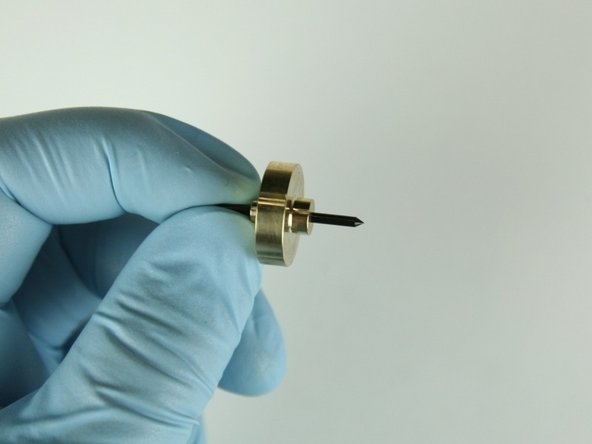

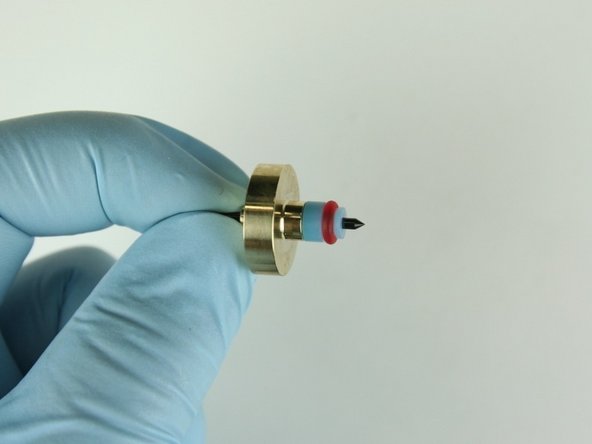

Slide the needle bearing onto the needle point with the larger stepped side pointing towards the needle point.

-

Slide the high-pressure valve seal onto the needle point.

-

Apply a high-pressure lubricant to the outside diameter of the high-pressure valve seal.

-

-

-

For similar assembly see Step 7 kit #13683 (parts/tools may vary)

-

-

-

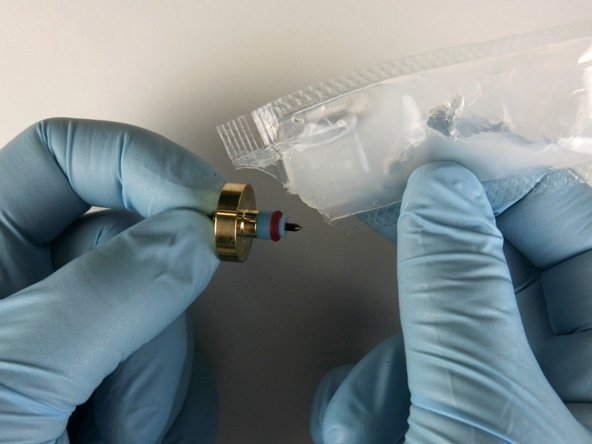

Clean the adapter of all Blue Goop with isopropyl alcohol or a similar cleaning agent.

-

Re-apply Blue Goop to the top threads and to the top of the adapter.

-

Put the seat in the adapter with the flat the side toward the adapter.

-

-

-

Apply Blue Goop to the top of the seat.

-

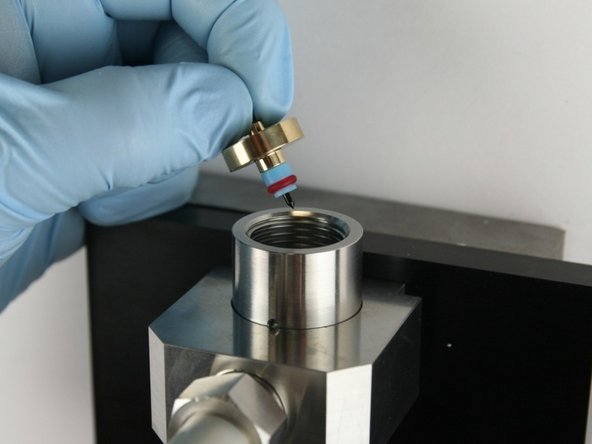

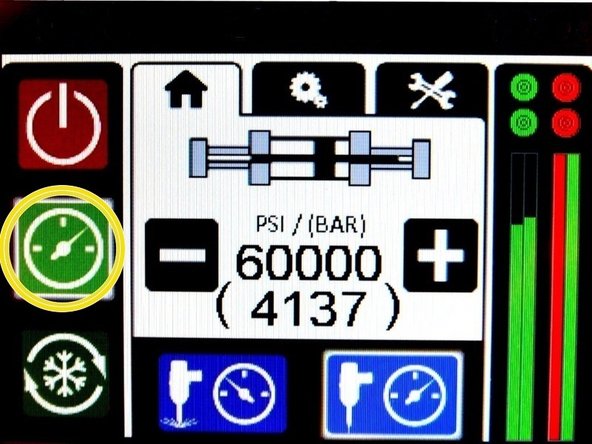

Turn the air to the actuator ON.

-

Thread the adapter into the valve body.

-

-

-

Tighten the adapter into the valve body using a 1" and 13/16" wrench.

-

Turn the air to the actuator OFF.

-

Apply water pressure to the valve assembly to verify there are no leaks.

-

-

-

Quickly cycle the valve on and off a few times to purge the system of all contaminants before installing the cutting head.

-

Reinstall the cutting head and continue the cutting process.

-