Parts

- Bleed Down Valve Body II #12943

- Bleed Down Valve Needle II #12942

- Bleed Down Valve High-Pressure Seal #11321

- Bleed Down Valve Seal Hoop #11323

- Bleed Down Valve Stem Bushing #11324

- Poppet Seat #11141

- Seal Back-up Screw #12945

- Outlet Adapter #12944

- Flow Reducer #11743

- Bleed Down Valve Housing Body #11779

- Bleed Down Valve Hydraulic Piston #11778

- Back-up O-Ring #11680-114

- Male to Female Hydraulic Adapter #11796

- O-ring SAE #12880-912

- O-ring Lube #13969

- High Vacuum Grease #11447

- Blue Goop #11111

- Isopropyl Alcohol

-

-

Always make sure all high-pressure water has been removed from valve by following machine manufacturers' safety instructions. Failure to do so can cause severe injury or death.

-

Turn OFF all hydraulic and water pressure to bleed-down valve

-

Loosen hydraulic hose from hydraulic fitting using 7/8" and 3/4" wrench

-

-

-

Unthread hose from hydraulic fitting

-

Loosen gland nut from side inlet of valve body

-

Unthread gland nut from side inlet of valve body

-

-

-

Clean gland nut of all blue goop with isopropyl alcohol

-

Loosen HP gland from outlet adapter using 13/16" and 1" wrench

-

Unthread HP gland from outlet adapter

-

-

-

Clean gland nut of all blue goop with isopropyl alcohol

-

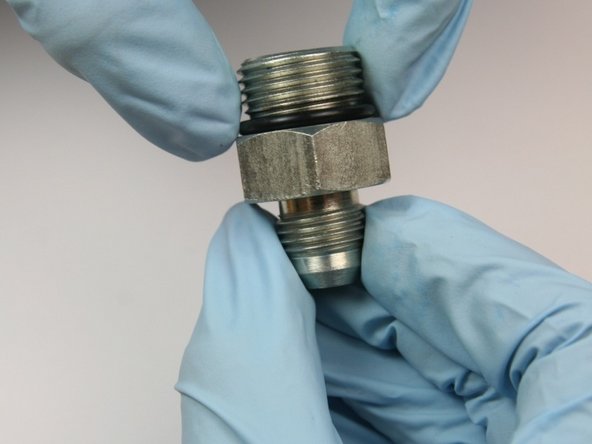

Loosen hydraulic fitting from adapter fitting using 1-1/4" and 7/8" wrench

-

Unthread hydraulic fitting from adapter fitting

-

-

-

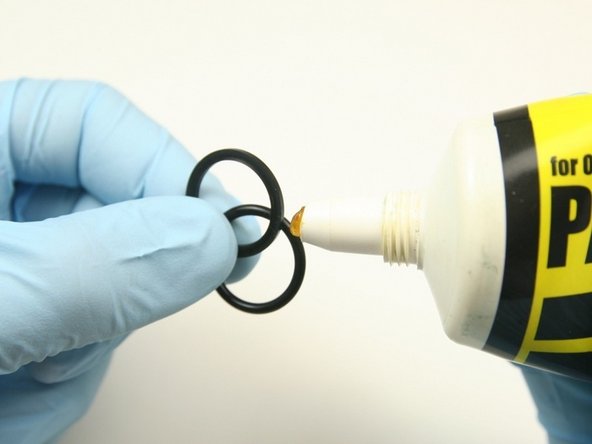

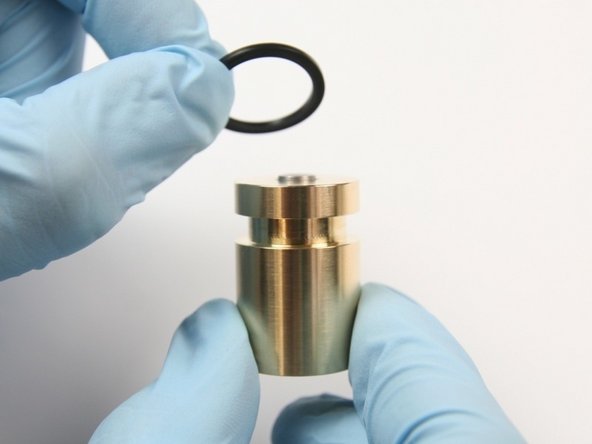

Apply o-ring lubricant to o-ring from kit for hydraulic fitting

-

Replace o-ring around hydraulic fitting with o-ring in kit (smallest o-ring in kit)

-

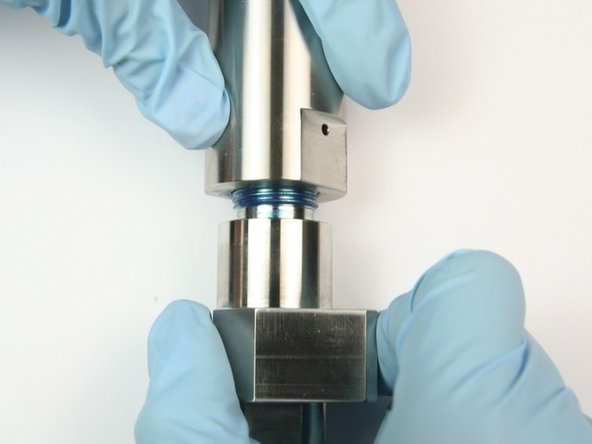

Loosen adapter fitting from Actuator Housing using 1-1/4" and 1-1/16" wrench

-

-

-

Unthread adapter fitting from actuator housing

-

Apply o-ring lubricant to largest o-ring in kit

-

Replace o-ring on adapter fitting with largest o-ring in kit

-

-

-

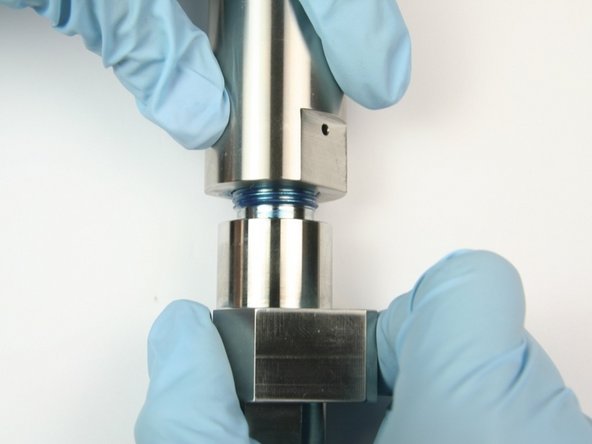

Loosen actuator housing from Valve Body using 1-1/16" and 7/8" wrench

-

Unthread actuator housing from valve body

-

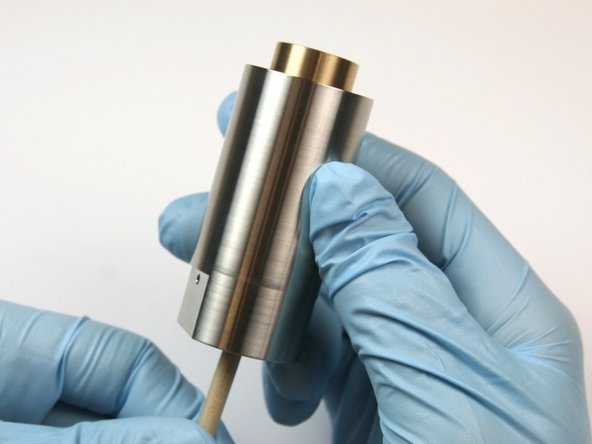

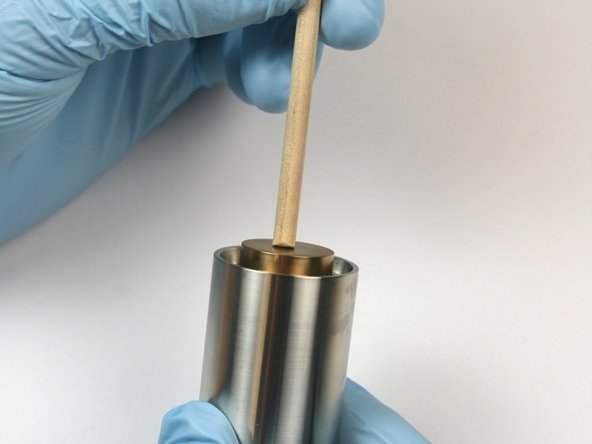

Push the Piston out of actuator housing through oil port using included dowel

-

-

-

Discard o-ring and backup ring from piston

-

Inspect piston, if damage is visible, replace

-

Apply o-ring lubricant to o-ring and back-up ring

-

-

-

Slide new back-up o-ring (flat) to groove of piston Make sure concave of back-up ring side is towards o-ring

-

Slide new o-ring (rounded) to groove of piston

-

Insert piston assembly into actuator housing and push with included dowel

-

-

-

Loosen outlet fitting from bleed down valve body using 7/8" and 13/16" wrench

-

Unthread outlet fitting from bleed down valve body

-

-

-

Remove HP Seat from bleed down valve body

-

Remove Flow Reducer from outlet adapter

-

-

-

Clean outlet adapter of all blue goop with isopropyl alcohol

-

Discard seat

-

Loosen back-up screw from top of bleed down valve body using a 5/16" ratchet

-

-

-

Unthread seal back-up screw from top of bleed down valve body

-

Clean seal back-up screw with isopropyl alcohol

-

Push components through bleed down valve body with included dowel

-

-

-

Clean bleed down valve body with isopropyl alcohol

-

Apply high vacuum grease to Needle

-

Slide back-up screw on to needle to flat end of needle is flush with non threaded part of back-up screw

-

-

-

Slide bushing onto point of needle with chamfered end towards back-up screw

-

Place hoop with tapered end onto onto HP Seal opposite from o-ring

-

Place HP seal assembly onto point of needle with hoop first

-

-

-

Apply high vacuum grease to exterior of HP seal, hoop, and bushing

-

Apply high vacuum grease to internal threads of bleed down valve body

-

Insert high pressure needle assembly into top of bleed down valve body with point first

-

-

-

Push seal backup screw inside of valve body until it bottoms out

-

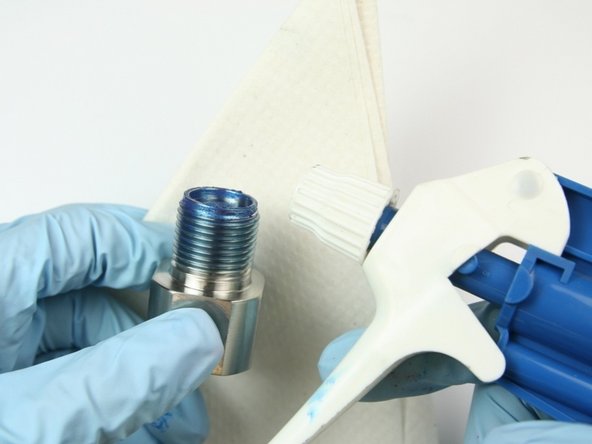

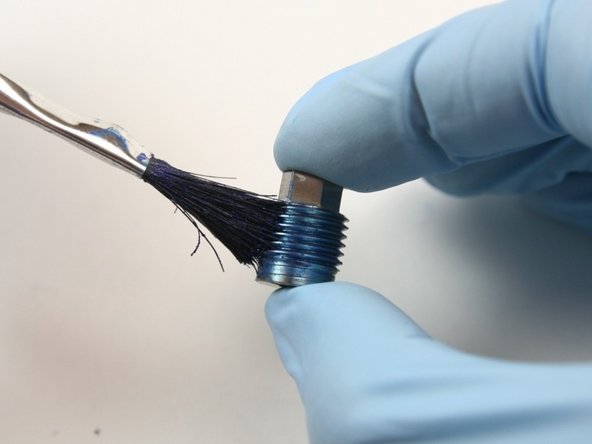

Take seal backup screw out of body and apply a layer of blue goop to threads

-

Thread in back-up screw into top of bleed down valve body

-

-

-

Tighten back-up screw to top of bleed down valve body using a 5/16" ratchet

-

Place flow reducer into hole beneath seat cavity in outlet adapter

-

Apply a layer of blue goop to external threads and seat cavity of outlet adapter

-

-

-

Place poppet seat into seat cavity of outlet adapter

-

Apply a layer of blue goop to top of poppet seat sitting in outlet adapter

-

Thread outlet adapter into valve body

-

-

-

Using a 1" wrench on outlet adapter and a 7/8" wrench on the valve body, tighten securely

-

Apply a layer of blue goop to external threads of valve body

-

Thread actuator housing onto valve body

-

-

-

Tighten using a 1-1/16" wrench on actuator housing and a 7/8" wrench on valve body

-

-

-

Apply blue goop to gland nut threads

-

Thread in gland nut with HP tubing into bleed down valve adapter

-

Tighten gland nut into bleed down valve adapter using 13/16" and 5/8" wrench

-

-

-

Apply blue goop to gland nut threads

-

Thread in gland nut to side of bleed down valve body

-

Tighten gland nut to side of bleed down valve body with using 3/4" and 5/8" wrench

-

-

-

Thread in adapter fitting into actuator housing

-

Tighten adapter fitting into actuator housing

-

Thread in hydraulic adapter into adapter fitting

-

-

-

Tighten hydraulic fitting into adapter fitting

-

Thread hydraulic hose to hydraulic fitting

-

Tighten hydraulic hose to hydraulic fitting using 7/8" and 3/4" wrench

-

-

-

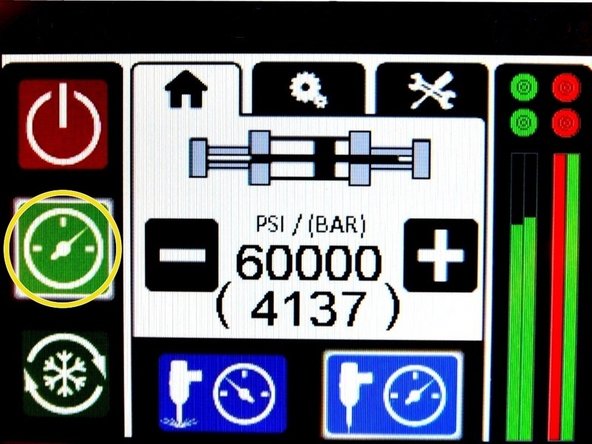

Turn pump ON and continue cutting process

-