-

-

-

The components can be replaced with the valve body in the mounting collar.

-

Loosen the adapter from the valve body using a 1" and 13/16" wrench.

-

Unthread the adapter from the valve body.

-

-

-

Unthread the actuator from the valve body.

-

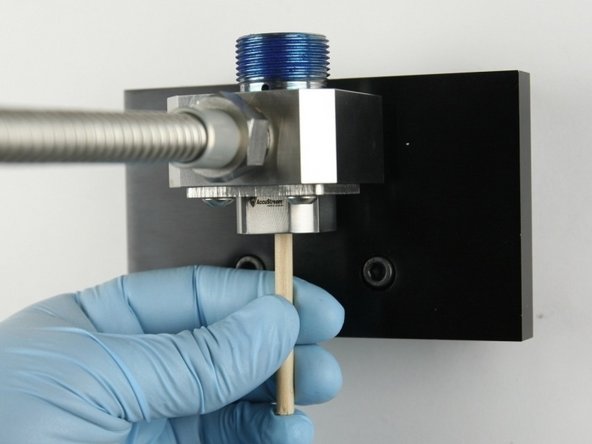

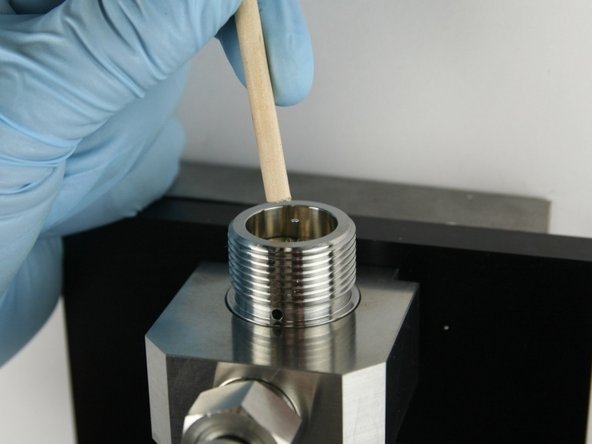

Remove all the valve components using the included dowel.

-

Thoroughly clean the interior/exterior of the valve body before replacing the components.

-

-

-

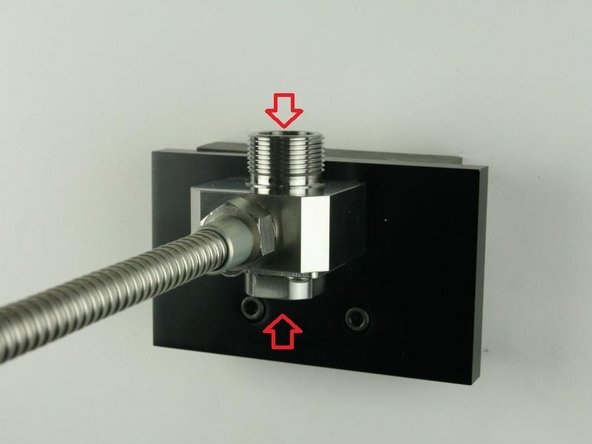

Make sure the top and bottom of the bore for cracks/blemishes. If excessive wear or cracks are visible, replace the valve body.

-

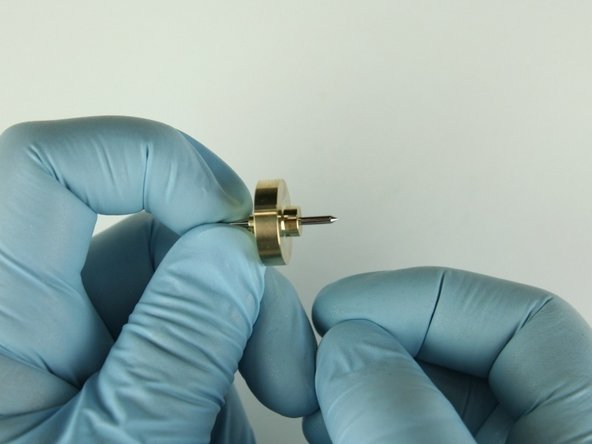

Slide the needle bearing onto the needle point with the smaller stepped side away from the needle point.

-

Slide the high-pressure valve seal onto the needle point with the O-ring away from the needle bearing.

-

-

-

Apply a high-pressure lubricant to the outside diameter of the high-pressure valve seal.

-

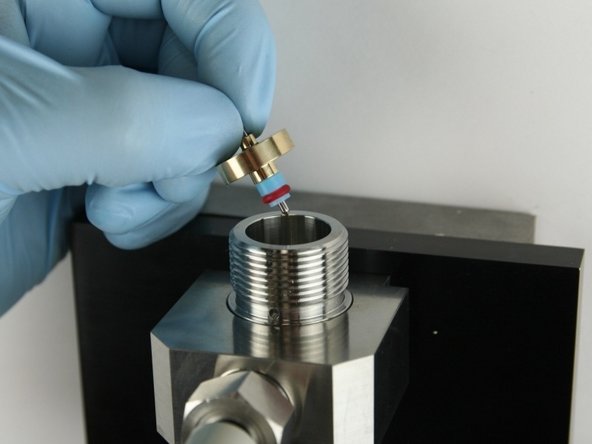

Put the needle point at the top of the valve body.

-

Use the dowel to push the needle in the valve body until the needle bearing bottoms out.

-

-

-

Reconnect the air line to the top of the actuator.

-

Clean the adapter of all Blue Goop with isopropyl alcohol or a similar cleaning agent.

-

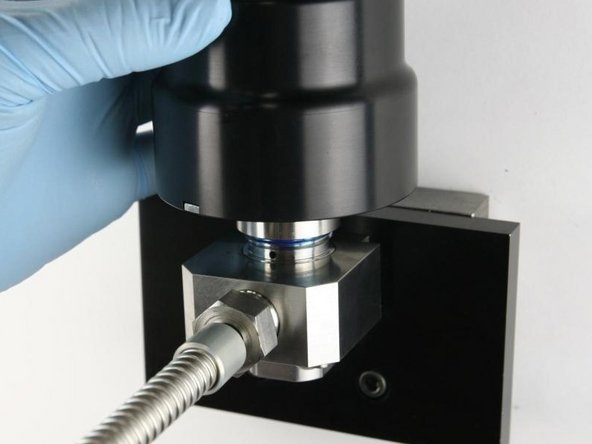

Reapply Blue Goop to the top threads and to the top of the adapter.

-

-

-

Put the seat at the top of the adapter with the flat side towards the adapter.

-

Apply Blue Goop to the top of the seat.

-

Turn the air to the actuator ON.

-

-

-

Thread the adapter into the valve body.

-

Tighten the adapter into the valve body using a 1" and 13/16" wrench.

-

Turn the air to the actuator OFF.

-

-

-

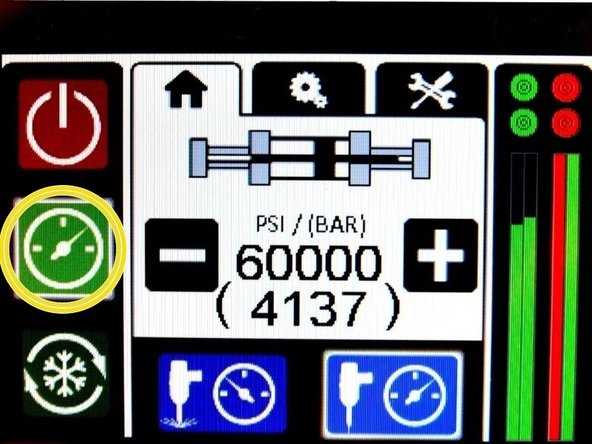

Apply water pressure to the valve assembly to verify that there are no leaks

-

Quickly cycle the valve on and off a few times to purge the system of all contaminants before installing the cutting head.

-

Reinstall the cutting head and continue the cutting process.

-

Cancel: I did not complete this guide.

9 other people completed this guide.