Tools

Parts

- High-Pressure Seal Kit #11451

- High-Pressure Seal with O-ring #11024 (included in kit)

- Hoop #11018 (included in kit)

- High-Vacuum Grease #11447 (included in kit)

- HP Cylinder #14766

- Spacer Tube #11521

- Low-Pressure Poppet Basket #11520

- AS Low-Pressure Poppet #11526

- Check Valve #14767

- -031 O-ring #11679-031

- -035 O-ring #11679-035

- AS HP Endcap #11529

- 1"-14 Grade 8 Nut #11672

- Blue Goop #11111

- O-ring Lube #13969

-

-

Always make sure all high-pressure water has been removed from pump by following machine manufacturers' safety instructions. Failure to do so can cause severe injury or death.

-

Remove HP cylinders and check valves from intensifier. Clean cylinders and check valves thoroughly, following standard procedures.

-

Scotch-Brite, or similar abrasive pad, can be used on sealing faces of cylinder and check valve to clean marking and/or galling.

-

-

-

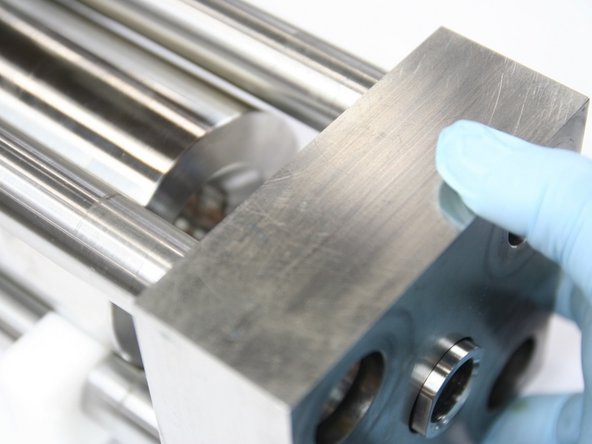

Place HP cylinder on seal installation spacer tool, taper side down

-

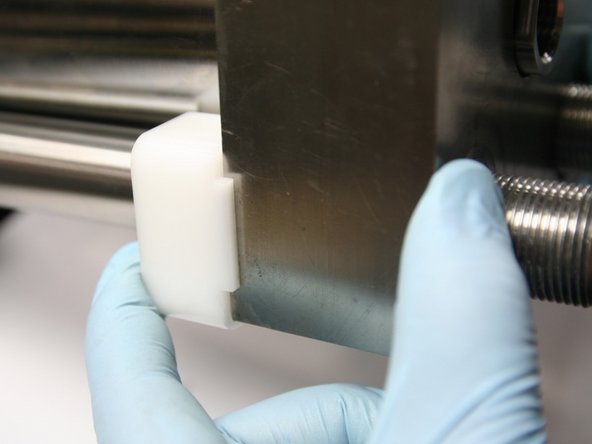

Apply light coat of high vacuum grease to both shoulders of spacer tube

-

Insert spacer tube into cylinder with LP poppet end down

-

-

-

Place locator tool on cylinder

-

Place sleeve in locator tool with taper end up

-

Apply light coat of high vacuum grease to red o-ring

-

-

-

Roll red o-ring into groove on HP seal

-

Insert assembled HP seal into sleeve with red o-ring down towards cylinder

-

Press HP seal into cylinder using non-stepped end of push tool

-

Hold down sleeve while inserting HP seal to ensure seal doesn't catch on edge of HP cylinder

-

-

-

Place hoop in sleeve with sharp edge of hoop down towards HP cylinder

-

Seat hoop in HP cylinder using non-stepped end of push tool and dead blow hammer

-

Hold down sleeve while seating hoop to ensure hoop doesn't catch on edge of HP cylinder

-

Remove locator tool, sleeve, and push tool

-

-

-

Apply a light coat of blue goop to outer face of inset on end of HP cylinder

-

Flip cylinder over and remove seal installation spacer tool

-

Insert LP poppet in LP poppet basket so stem of poppet goes through center hole in basket

-

Make sure LP poppet can freely move in LP poppet basket

-

-

-

Insert LP poppet and LP poppet basket into spacer tube in HP cylinder

-

Place seal installation spacer tool on end of HP cylinder with step side down

-

Place mounting cradle on bottom studs of intensifier with tabs toward outside of intensifier

-

-

-

Push HP cylinder onto plunger using mounting cradle as a guide and seal installation spacer tool as a push tool

-

Remove seal installation spacer tool, taking care to that LP poppet stays in LP poppet basket

-

Apply light coat of o-ring lube to -035 and -031 o-rings for check valve

-

-

-

Place -031 and -035 o-rings into grooves on check valve

-

Apply light coat of blue goop to tapered (sealing) face of check valve

-

Apply light coat of blue goop to bottom step of check valve

-

-

-

Insert check valve into HP endcap

-

Slide HP endcap with check valve onto intensifier studs

-

Push HP endcap against HP cylinder and align tabs of mounting cradle so cradle supports HP endcap

-

The mounting cradle is used to ensure proper alignment between HP cylinder an HP endcap during torquing

-

-

-

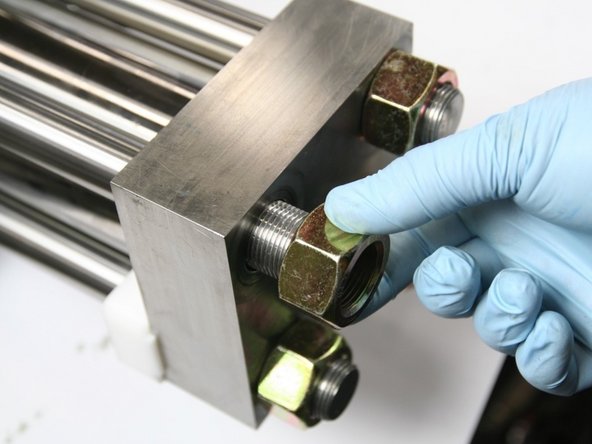

Thread and hand-tighten nuts onto studs using a cross pattern

-

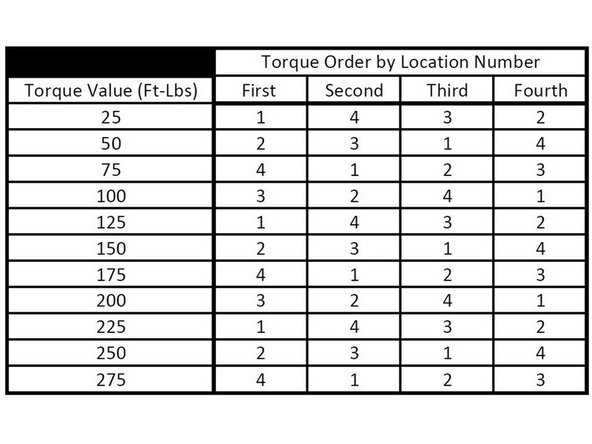

Torque nuts using a cross pattern according to the following directions

-

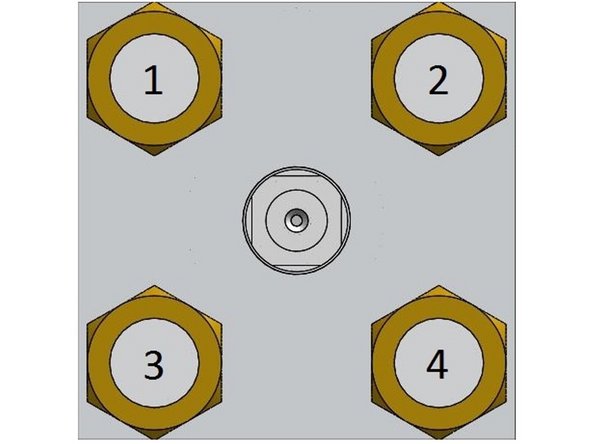

Use numbers in picture as a guide for location number found in included table for torquing procedure

-

-

-

Torque each nut in torque order found in table to each torque value prior to stepping to next value

-

Continue with HP poppet installation and standard start-up procedures

-

Cancel: I did not complete this guide.

One other person completed this guide.