Introduction

Hypertherm is in no way affiliated with the above mentioned manufacturer

Tools

Parts

- Pneumatic Valve Repair Kit #14323

- Bronze Back-up Ring #14314 (included in kit)

- High-Pressure Seal Assembly #14322 (included in kit)

- O-ring #11240 (included in kit)

- Seat #11099 (included in kit)

- Actuator #12089

- Valve Body #14317

- Valve Stem #14310

- Stainless Steel Back-up Ring #12733

- High-Pressure Gland Fitting #12347

- Nozzle Tube #11436

- Blue Goop #11111

-

-

Always make sure all high-pressure water has been removed from the valve by the following machine manufacturers' safety instructions. Failure to do so can cause severe injury or death.

-

Turn OFF all water pressure to the on/off valve.

-

Turn the On/Off valve ON to make sure there is no pressurized water in the valve.

-

-

-

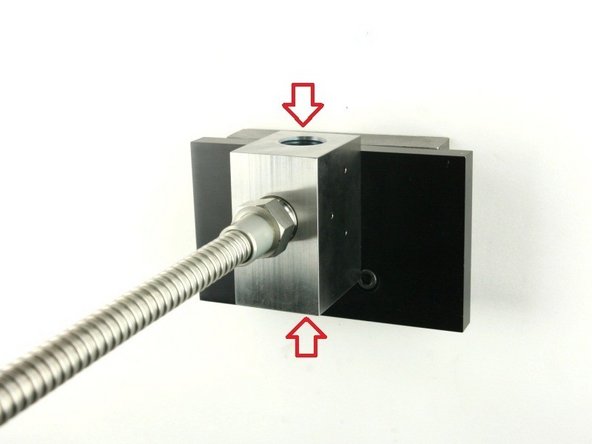

Valve components can be replaced with the valve body mounted to the table.

-

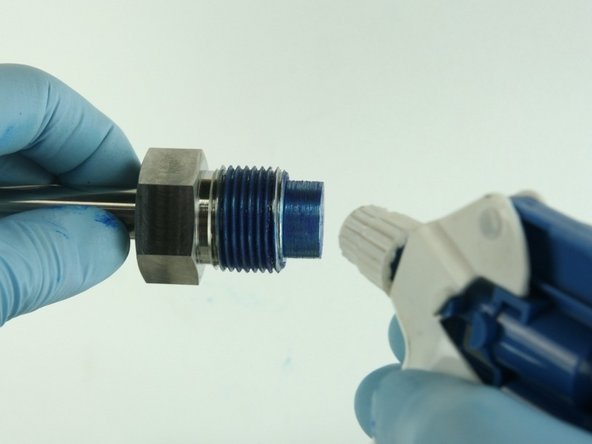

Loosen the high-pressure gland fitting using a 1-1/4" wrench.

-

Unthread high-pressure gland fitting from the valve body.

-

-

-

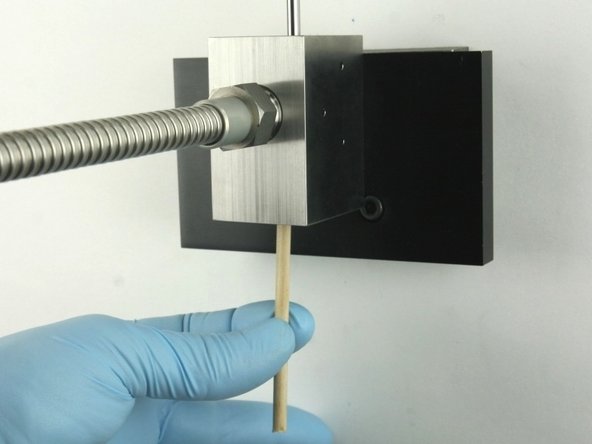

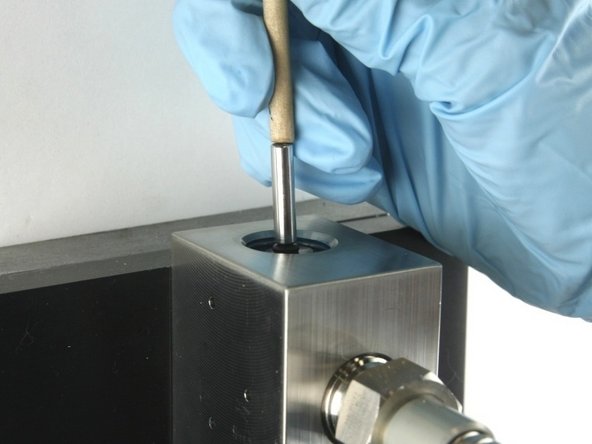

Remove all the valve components from the valve body with the included dowel.

-

Thoroughly clean the interior of the valve body with isopropyl alcohol or a similar cleaning agent before replacing the components.

-

Visually inspect the top and bottom of the valve bore for cracks/blemishes. If excessive wear or cracks are visible, replace the valve body.

-

-

-

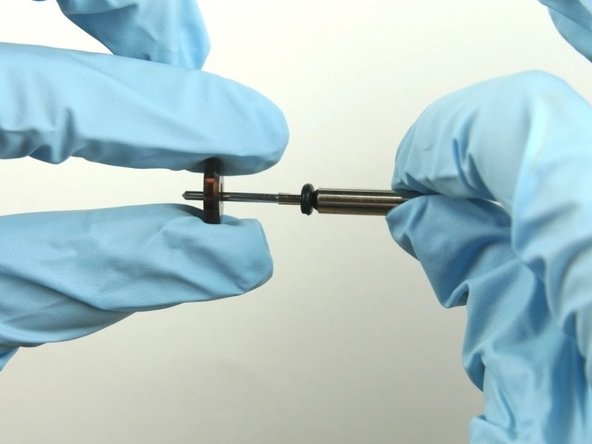

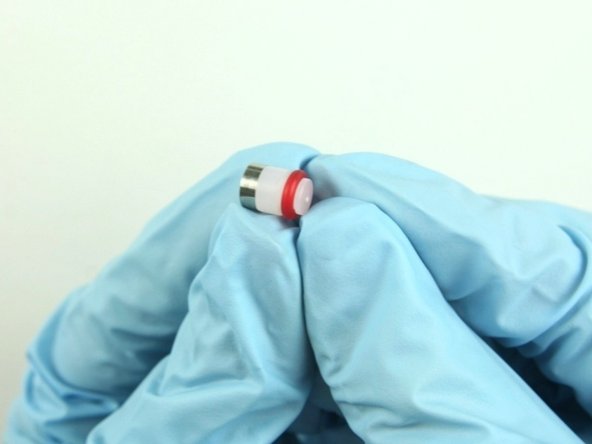

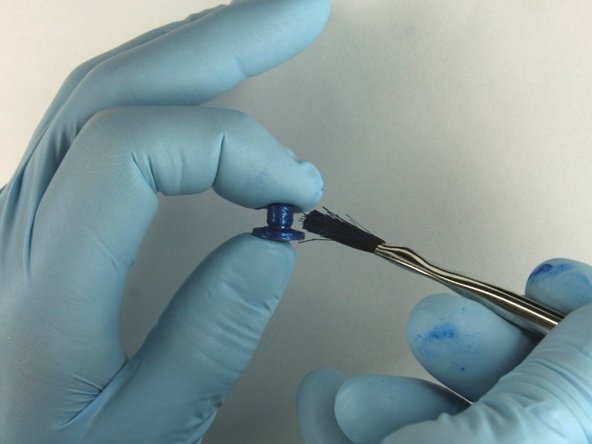

Slide the O-ring on to the point of the valve stem.

-

Slide the stainless steel back-up ring on to the valve stem point with the chamfer side towards O-ring.

-

Slide the brass back-up ring on to the valve stem point with the chamfer side away from the stainless steel back-up ring.

-

-

-

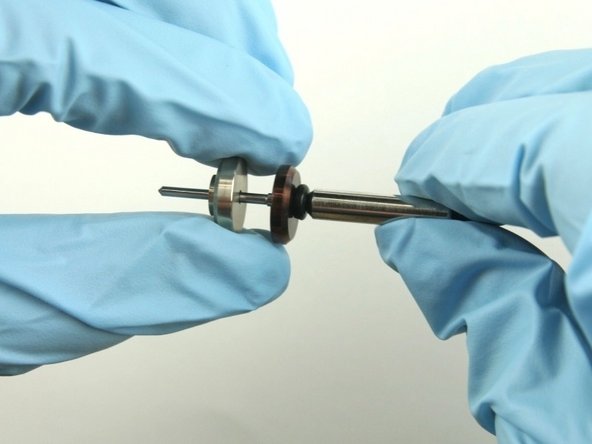

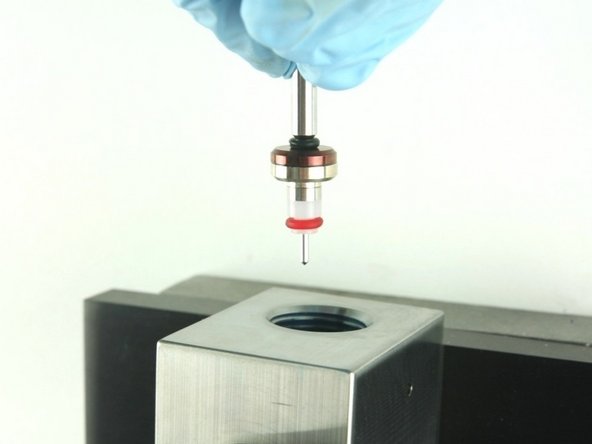

Put the hoop on the high-pressure seal with the sharp edge of the hoop towards the seal.

-

Slide the hoop and the high-pressure valve seal onto the valve stem with the hoop towards the brass back-up ring.

-

Apply high vacuum grease to the outside diameter of the high-pressure valve seal.

-

-

-

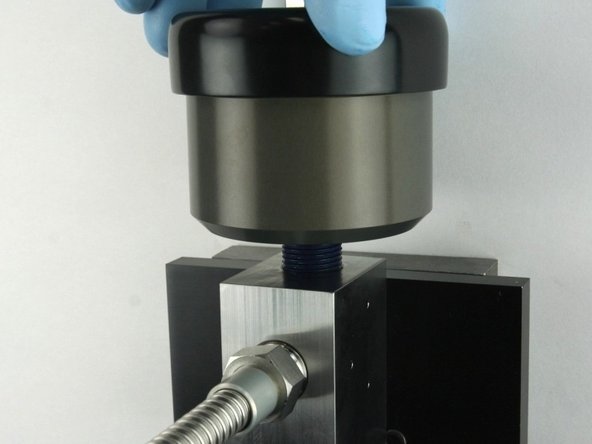

Thread (hand tighten) the actuator into the top of the valve body until it bottoms out.

-

Reconnect the air line to the top of actuator.

-

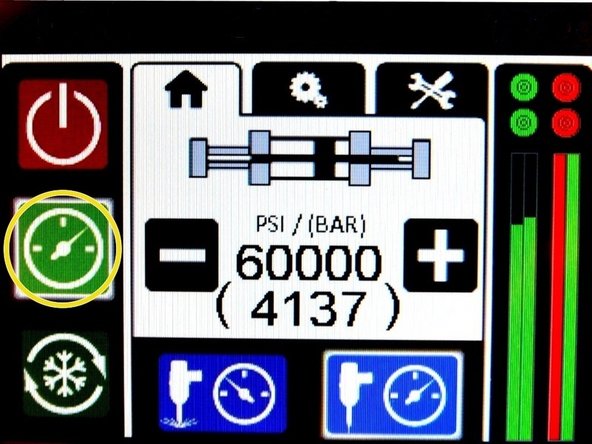

Turn the air to the actuator ON at the controls.

-

-

-

Apply Blue Goop to all surfaces of the seat.

-

Put the seat into the bottom of the valve body.

-

Clean the valve nut threads and the top of the nozzle tube of all Blue Goop.

-

-

-

Reapply Blue Goop to the threads of the high-pressure gland fitting and to the top of the nozzle tube.

-

Thread the high-pressure gland fitting into the bottom of the valve body.

-

Tighten the high-pressure gland fitting using a 1-1/4" wrench.

-

-

-

Turn the air to the actuator OFF at the controls.

-

Apply water pressure to the valve assembly to verify there are no leaks.

-

Quickly cycle the valve on and off a few times to purge the system of all contaminants before installing the cutting head.

-

-

-

Re-install the cutting head and continue the cutting process.

-