Introduction

Hypertherm is in no way affiliated with the above mentioned manufacturer.

Parts

-

-

Always make sure all high pressure water has been removed from valve by following machine manufacturers' safety instructions. Failure to do so can cause severe injury or death.

-

Turn OFF all water pressure to on/off valve.

-

Turn on/off valve ON to raise needle from seat.

-

-

-

Valve kit components can be replaced with valve body in mounting collar.

-

With air to actuator ON, unscrew nozzle tube from valve body using a 1" and 13/16" wrench.

-

Turn air actuator OFF at controls and unscrew actuator from valve body using a 7/8" wrench.

-

-

-

Remove old valve components from valve body with included dowel.

-

Thoroughly clean interior of valve body with isopropyl alcohol or similar cleaning agent before replacing components.

-

Visually inspect top and bottom of valve bore for cracks or blemishes.

-

-

-

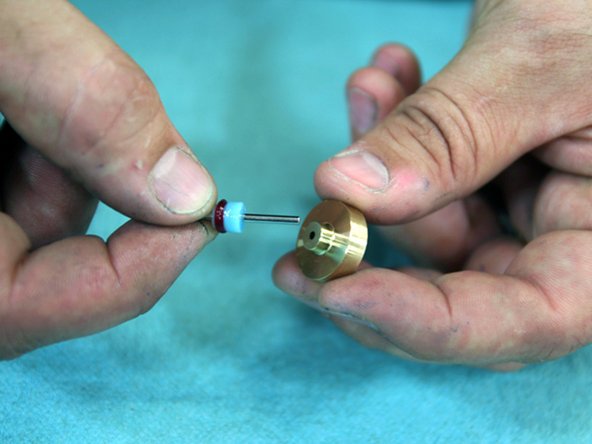

Insert Needle through HP Seal. Make sure the red o-ring is facing towards needle tip.

-

Apply o-ring lubricant to outside diameter of HP Seal.

-

Slide Needle Guide onto the back end of the Needle. Make sure larger diameter end of Needle Guide faces towards HP Seal.

-

-

-

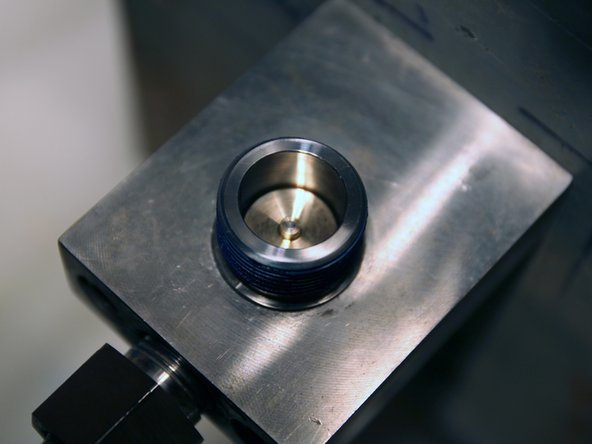

Insert assembly into bore of valve body.

-

Press assembly into place, using included dowel, until Needle Guide bottoms on valve bore.

-

-

-

Thread (hand tighten) actuator onto top of valve body

-

Reconnect air line to top of actuator and

-

turn air to actuator ON to relieve pressure from needle

-

-

-

Make sure to thoroughly clean nozzle tube with isopropyl alcohol or similar cleaning agent. Visually inspect nozzle tube for cracks or blemishes.

-

Apply Blue Goop (11111) to top of nozzle tube and insert Seat.

-

Apply Blue Goop to surfaces at top of Seat and to surface of Seat where Needle sits.

-

-

-

With actuator turned ON, thread nozzle tube into bottom of valve body.

-

Torque adapter to valve using two wrenches (1" and 13/16").

-

Turn air to actuator OFF to seat Needle into Seat.

-

-

-

Apply water pressure to valve assembly to verify there are no leaks.

-

Quickly cycle valve on and off a few times to purge system of all contaminats before installing cutting head.

-

Re-install cutting head and continue cutting process.

-

Cancel: I did not complete this guide.

One other person completed this guide.