Introduction

Hypertherm is in no way affiliated with the above mentioned manufacturer

-

-

Always make sure all high-pressure water has been removed from the valve by following the machine manufacturers' safety instructions. Failure to do so can cause severe injury or death.

-

Turn OFF all water pressure to the on/off valve.

-

Turn the on/off valve ON to raise the poppet stem from the high-pressure seat.

-

-

-

The valve kit components can be replaced with the valve body in the mounting collar.

-

Loosen the nozzle tube from the valve body using a 3/4" and 7/8" wrench.

-

Unthread the nozzle tube from the valve body.

-

-

-

Remove the old valve components from the valve body with the included dowel.

-

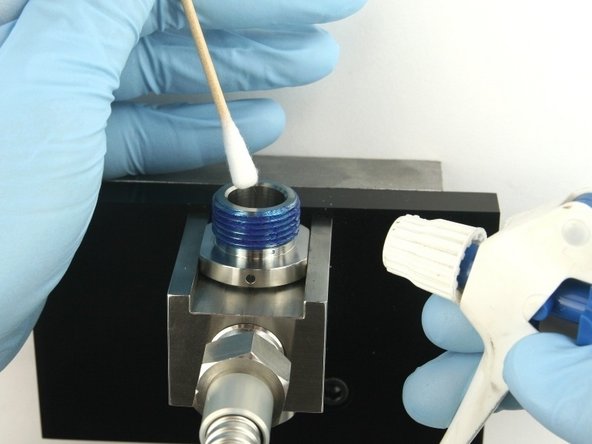

Thoroughly clean the interior/exterior of the valve body with isopropyl alcohol or similar cleaning agent before replacing the components.

-

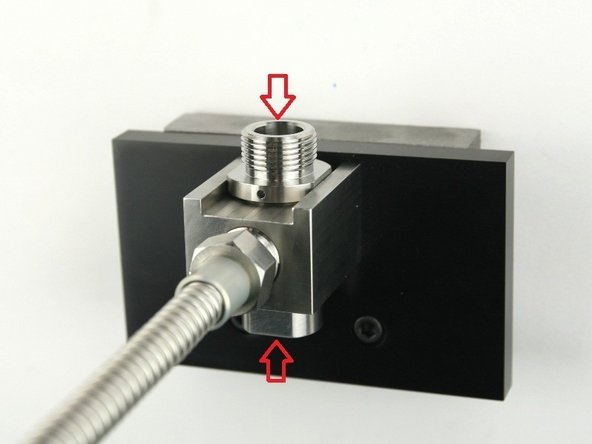

Visually inspect the top and bottom of the bore for cracks/blemishes. If excessive wear or cracks are visible, replace the valve body.

-

-

-

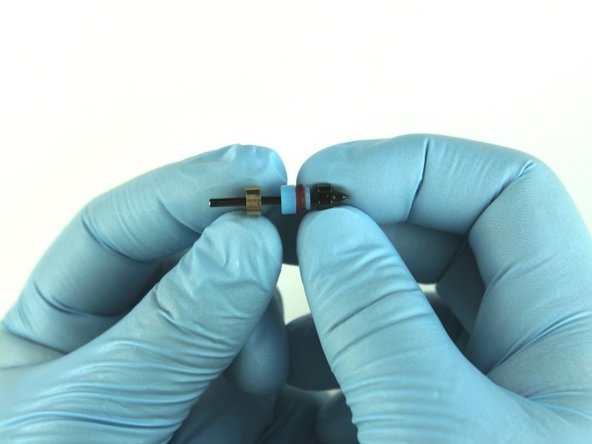

With the O-ring towards the point of the poppet stem, slide the high-pressure valve seal on to the poppet stem.

-

Apply a high-pressure lubricant or similar (11336) to the outside diameter of the high-pressure valve seal.

-

Slide the back-up ring on to the poppet stem behind the high-pressure valve seal.

-

-

-

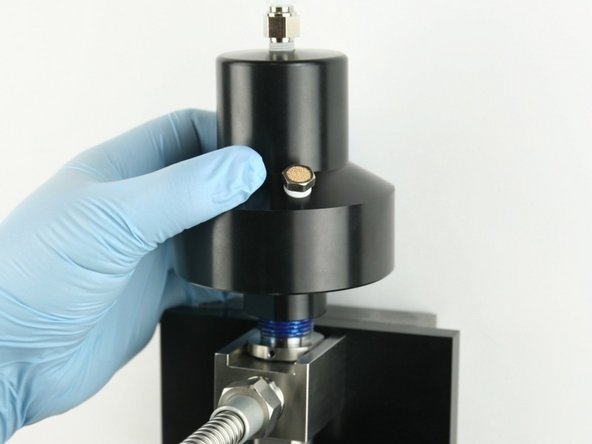

Thread (hand tighten) the actuator to the top of the valve body.

-

Reconnect the air line to the top of the actuator.

-

Turn the air to the actuator ON to relieve the pressure from the poppet stem.

-

-

-

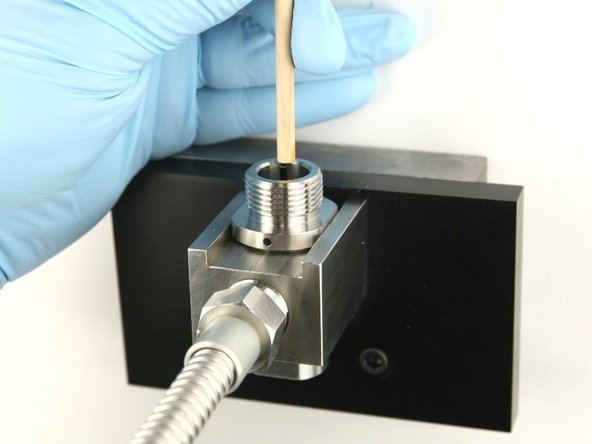

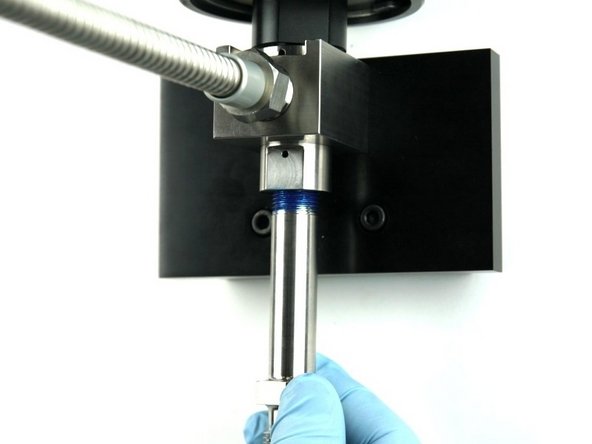

Thoroughly clean the nozzle tube of all the Blue Goop.

-

Reapply Blue Goop to the threads of the nozzle tube.

-

Thread the nozzle tube into the bottom of the valve body.

-

-

-

Tighten the nozzle tube to the valve body using a 3/4" and 7/8" wrench.

-

Turn the air to the actuator OFF to set the poppet stem into the high-pressure seat.

-

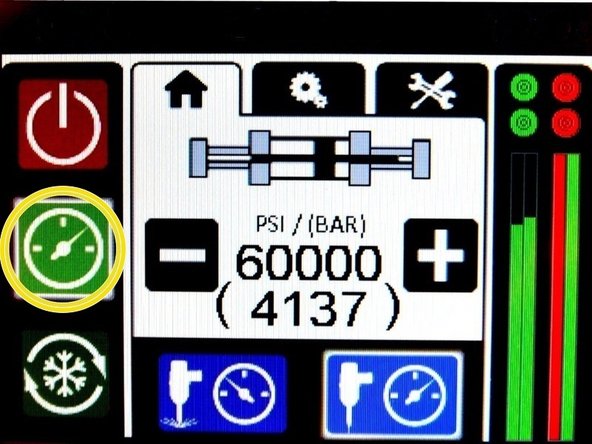

Apply water pressure to the valve assembly to verify there are no leaks.

-

-

-

Quickly cycle the valve on and off a few times to purge the system of all contaminants before installing the cutting head.

-

Re-install the cutting head and continue the cutting process.

-

Cancel: I did not complete this guide.

2 other people completed this guide.