Tools

Parts

- High-Pressure Seal Kit #11451

- Hoop #11018 (included in kit)

- High-Pressure Seal with O-ring #11024 (included in kit)

- High-Vacuum Grease #11447 (included in kit)

- AS Low-Pressure Poppet #11526

- Low-Pressure Poppet Basket #11520

- Spacer Tube #11521

- AS High-Pressure Cylinder #11522

- Blue Goop #11111

- Isopropyl Alcohol

-

-

Loosen the check valve by tapping with a rubber mallet while rolling the cylinder.

-

Remove the check valve from the high-pressure cylinder

-

Remove the low-pressure poppet from the high-pressure cylinder.

-

-

-

Put the high-pressure cylinder onto the locator tool.

-

Put the stepped end of the push tool into the top of the high-pressure cylinder.

-

Hit the push tool with a rubber mallet to push out the high-pressure seal and hoop

-

-

-

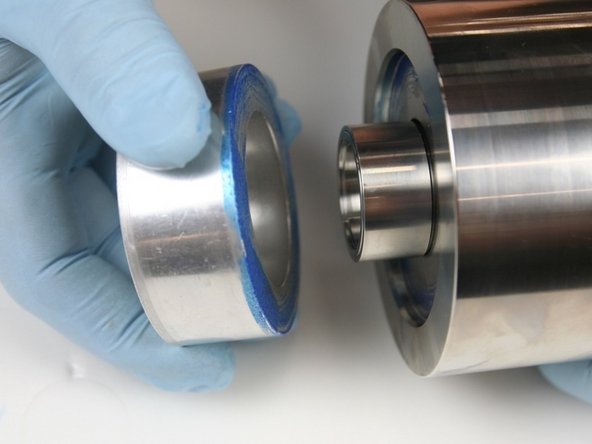

Remove the hoop and the high-pressure seal assembly from the end of the high-pressure cylinder.

-

Remove the locator tool from the high-pressure cylinder.

-

Flip the high-pressure cylinder and place it onto the locator tool.

-

-

-

Push the spacer tube down until it bottoms out.

-

Put the nonstepped end of the push tool into the high-pressure cylinder.

-

Hit the push tool with a rubber mallet to push the second hoop and the high-pressure seal assembly out of the high-pressure cylinder.

-

-

-

Remove the hoop and high-pressure seal assembly from the high-pressure cylinder.

-

Remove the locator tool from the high-pressure cylinder.

-

Remove the spacer tube and low-pressure poppet basket from the high-pressure cylinder.

-

-

-

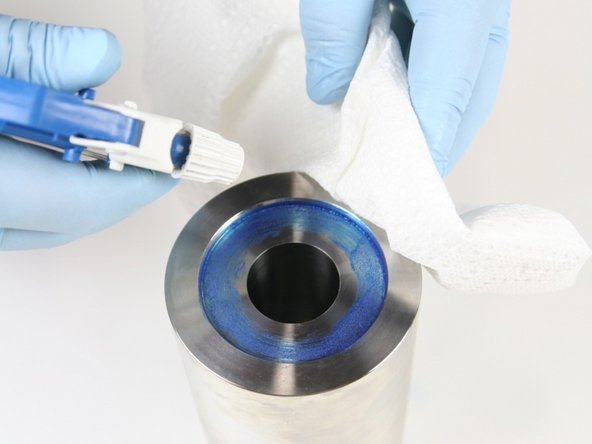

Roll scouring pad in both ends of the bore of the high-pressure cylinder to remove any blemishes.

-

Clean the high-pressure cylinder once more to remove all excess material from Scotch Brite

-

Put the high-pressure cylinder onto the high-pressure seal installation spacer tool.

-

-

-

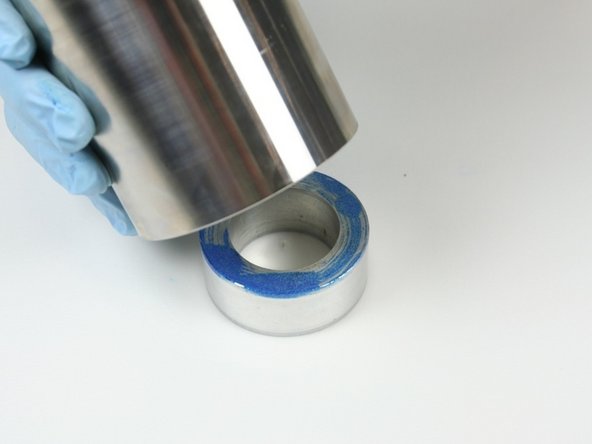

Apply a light coat of high vacuum grease to both ends of the spacer tube.

-

Put the low-pressure poppet into the low-pressure poppet basket with the stem of the poppet facing basket.

-

Make sure that the low-pressure poppet moves freely in the low-pressure poppet basket.

-

-

-

Put the low-pressure poppet and basket into the spacer tube.

-

Put the spacer tube with the poppet and basket up into the high-pressure cylinder.

-

Put the locator tool onto the high-pressure cylinder.

-

-

-

Put the sleeve into the locator tool with the tapered end up.

-

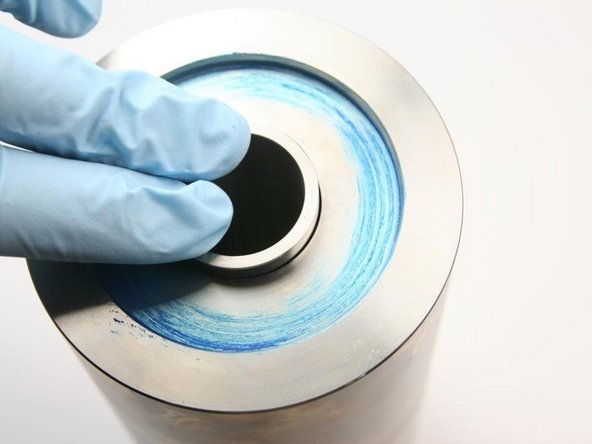

Apply high vacuum grease to the O-rings.

-

Put the O-rings onto the high-pressure seals.

-

-

-

Put the high-pressure seal into the sleeve with the O-ring down.

-

Put the non-stepped end of the push tool into the sleeve and press the high-pressure seal into the high-pressure cylinder until it bottoms out.

-

Hold the sleeve down against the cylinder with one hand to be sure it doesn't raise up while installing the seal.

-

Put the hoop into the sleeve with the tapered end down towards the high-pressure seal.

-

-

-

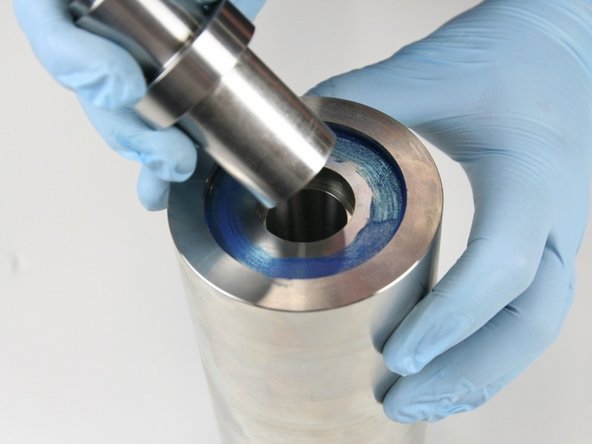

Put the non-stepped end of the push tool into the sleeve and be sure that the tool is level with the sleeve.

-

Use a rubber mallet to set the hoop into the high-pressure cylinder (until the push tool bottoms out).

-

Hold the sleeve down against the cylinder with one hand to be sure it doesn't raise up while installing the hoop.

-

Remove the installation tools from the top of the high-pressure cylinder.

-

-

-

Put the check valve on the high-pressure cylinder.

-

Use a rubber mallet to tap the check valve into the high-pressure cylinder.

-

Flip the high-pressure cylinder over so the cylinder is resting on the check valve.

-

-

-

Remove the seal installation spacer tool from the end of the high-pressure cylinder.

-

Put the locator tool on the high-pressure cylinder.

-

Put the sleeve into the locator tool with the tapered end up.

-

-

-

Put the high-pressure seal into the sleeve with the o-ring down.

-

Put the non-stepped end of the push tool into the sleeve and press the high-pressure seal into the high-pressure cylinder until it bottoms out.

-

Hold the sleeve down against the cylinder with one hand to be sure it doesn't raise up while installing the seal.

-

Put the hoop into the sleeve with the tapered end down towards the high-pressure seal.

-

-

-

Put the non-stepped end of the push tool into the sleeve and be sure that the tool is level with the sleeve.

-

Use a rubber mallet to set the hoop into the high-pressure cylinder (until the push tool bottoms out).

-

Hold the sleeve down against the cylinder with one hand to be sure it doesn't raise up while installing the hoop.

-

Remove the installation tools from the top of the high-pressure cylinder.

-

-

-

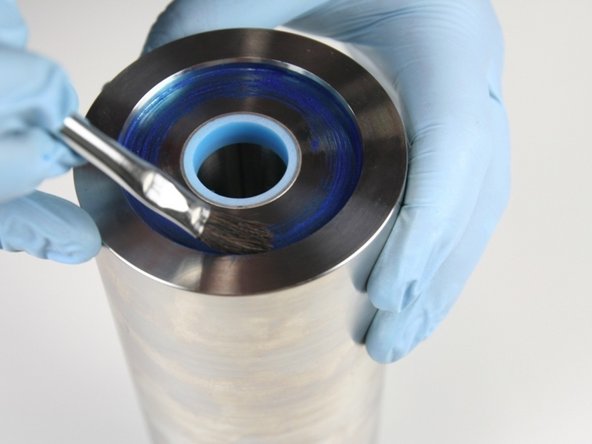

Apply Blue Goop to the outer edge of the high-pressure cylinder inset.

-

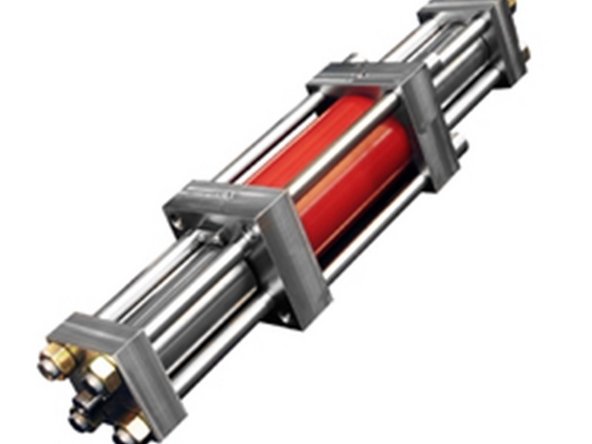

Continue with the installation with the high-pressure cylinder onto the intensifier.

-

Cancel: I did not complete this guide.

22 other people completed this guide.