Introduction

Hypertherm is in no way affiliated with the above mentioned manufacturer.

-

-

Remove the high-pressure cylinder(s) from the pump.

-

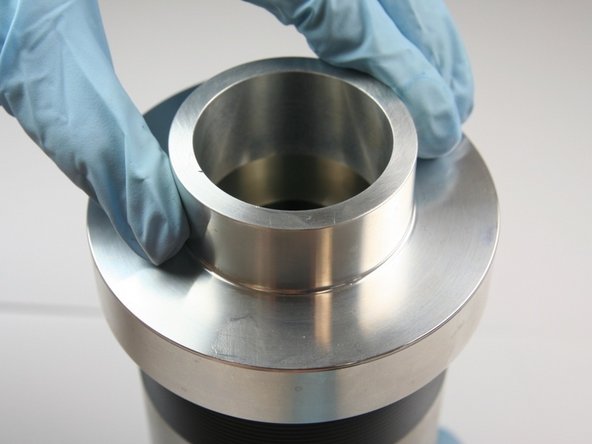

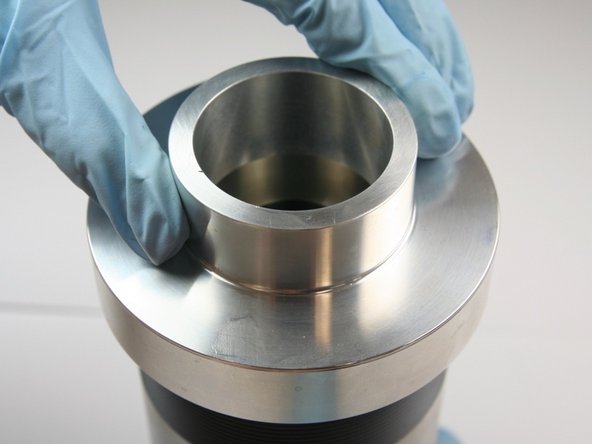

Put the cylinder on the Seal Guide tool

-

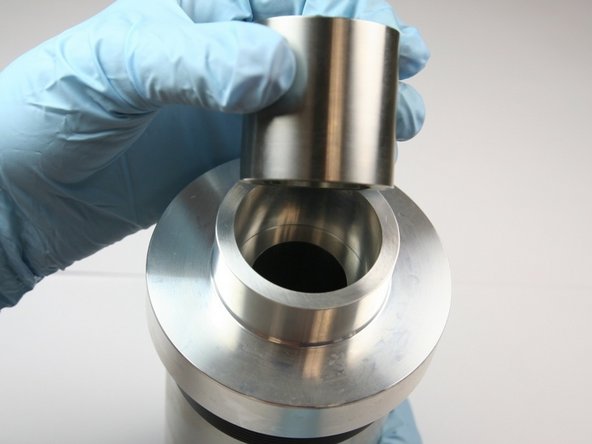

Put the small (stepped) end of the installation tool into the top of the high pressure cylinder.

-

-

-

Use a rubber mallet to push the internal back-up seal sleeve through the high-pressure cylinder forcing the seal and the hoop out of the other end of the high pressure cylinder.

-

Do not remove the sleeve from the high-pressure cylinder.

-

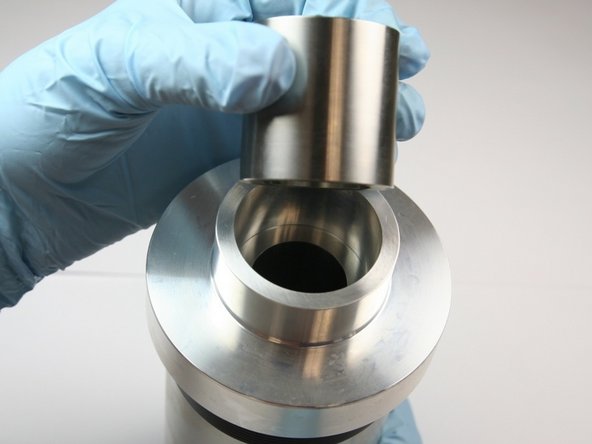

Turn the high-pressure cylinder over so the dynamic end is facing up.

-

Put the non-stepped end of the installation tool in the dynamic side of the high-pressure cylinder, push the other seal out by tapping with a rubber mallet.

-

-

-

Clean the high-pressure cylinder thoroughly after polishing.

-

Visually inspect the high-pressure cylinder bore at both ends.

-

If the inside bore finish is blemished, use Scotch Brite in both ends of the high-pressure cylinder to smooth out the blemishes by rolling back and forth.

-

-

-

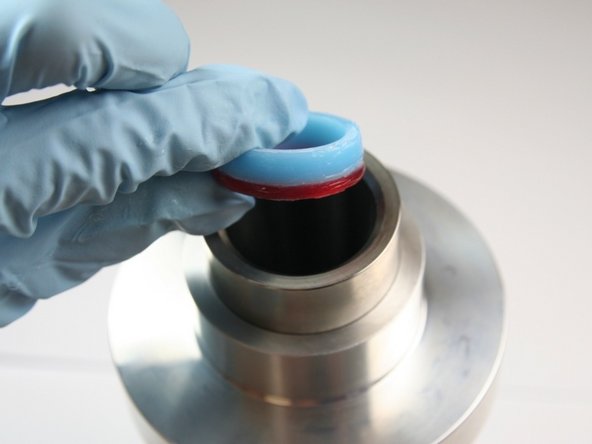

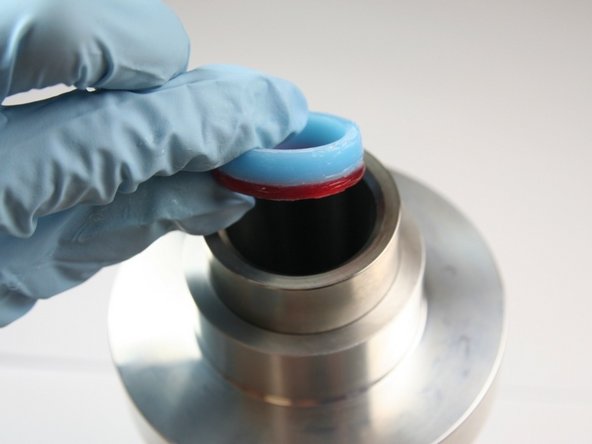

Apply a high vacuum grease to the O-rings.

-

Put the O-rings onto the high-pressure seals.

-

Be sure not to twist the O-rings when installing onto the high-pressure seals.

-

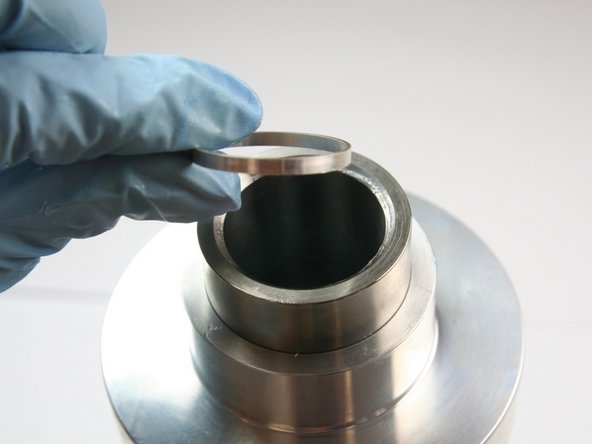

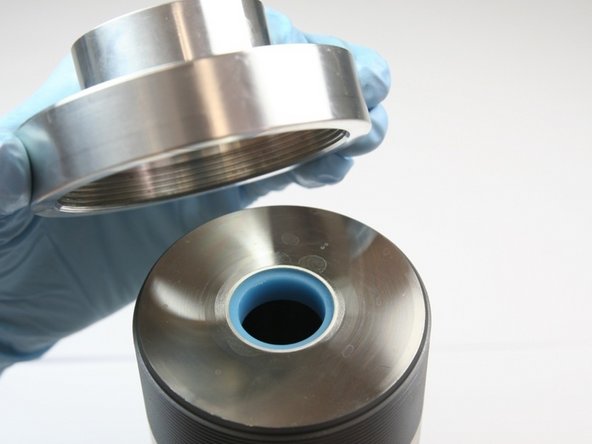

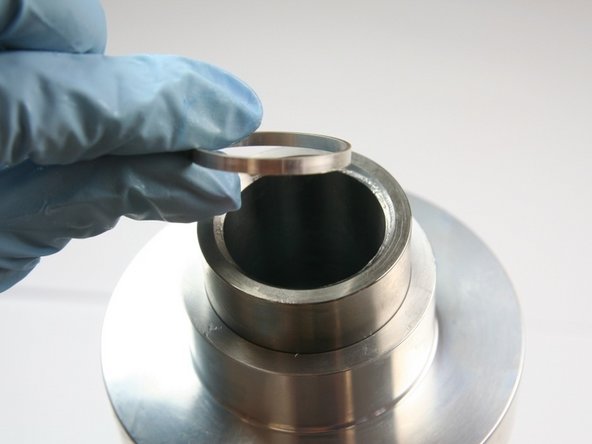

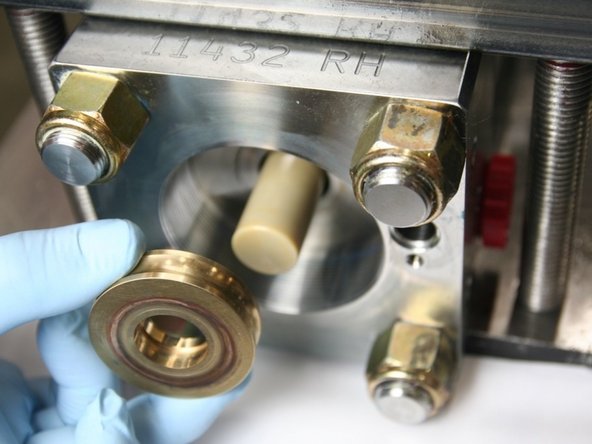

Thread the seal guide tool onto the static end of the high-pressure cylinder.

-

It is helpful to begin with the flat end of the high-pressure cylinder side up.

-

-

-

Put the installation sleeve into the sleeve guide with the larger ID (tapered) end up.

-

Lubricate the ID of the Installation sleeve with a high vacuum grease

-

Put the high-pressure seal into the sleeve with the O-ring side down.

-

-

-

Use the blunt (non-stepped) end of the installation tool to hand press the high pressure seal into the the high-pressure cylinder.

-

Put the hoop into the sleeve with the sharp (tapered) end first.

-

Push the hoop down into the sleeve with the blunt end of the installation tool.

-

-

-

Secure hoop in place by tapping installation tool in with a rubber mallet until tool bottoms on high-pressure cylinder face

-

Remove seal guide tools from top of high-pressure cylinder (static side)

-

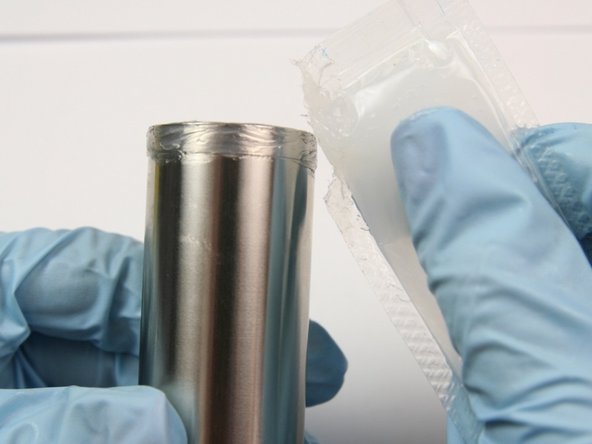

Apply a light coat of high vacuum grease to both ends of back-up seal sleeve

-

-

-

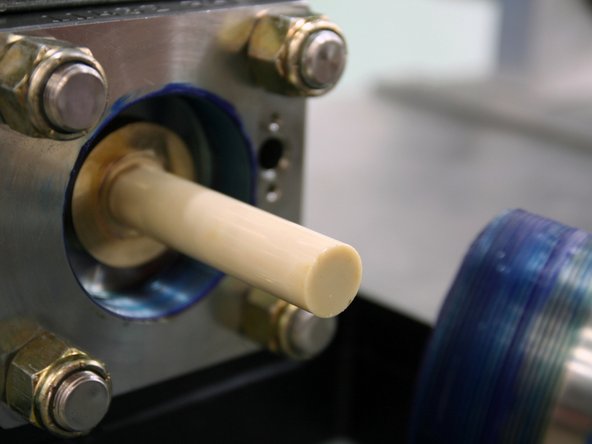

Put the sleeve into the open end of the high-pressure cylinder and repeat the seal installation process.

-

Thread the seal guide tool onto the dynamic side of the high-pressure cylinder.

-

Put the sleeve into the seal guide tool with the tapered end side facing up.

-

-

-

Apply a high vacuum grease to the ID of the sleeve.

-

Put the high-pressure seal assembly into the sleeve with the o-ring first.

-

Use the blunt (non-stepped) end of the installation tool to hand press the high-pressure seal into the high-pressure cylinder.

-

-

-

Put the hoop into the sleeve with the sharp (tapered) end first.

-

Push the hoop down into the sleeve with the blunt end of the installation tool.

-

Secure the hoop in place by tapping the installation tool in with a rubber mallet until the tool bottoms out on the high-pressure cylinder face.

-

-

-

Remove the seal guide tools from the dynamic side of the high-pressure cylinder.

-

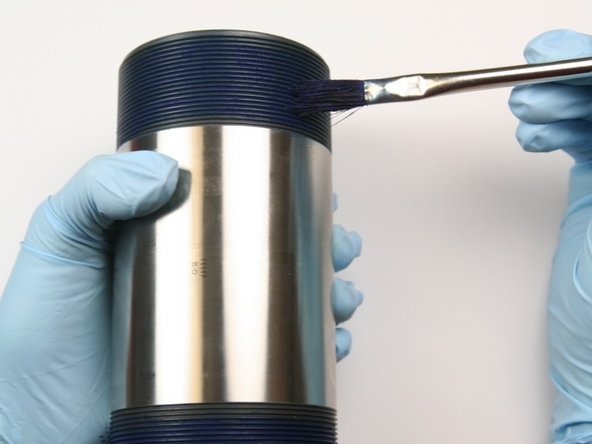

Apply blue goop to both threads of the high-pressure cylinder.

-

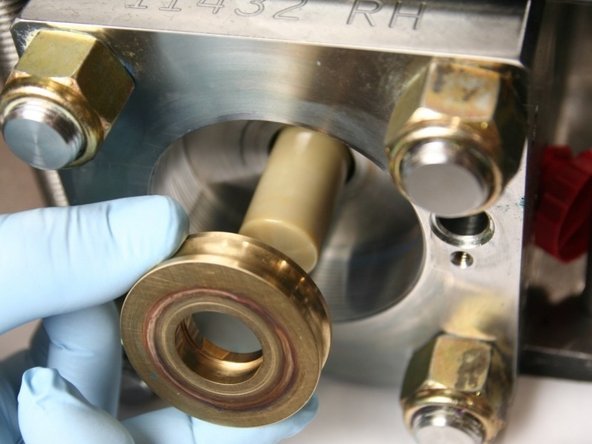

Remove the old bronze back-up ring from the plunger.

-

Cancel: I did not complete this guide.

3 other people completed this guide.