Introduction

Hypertherm is in no way affiliated with the above mentioned manufacturer.

-

-

Remove the high-pressure cylinder(s) from the pump.

-

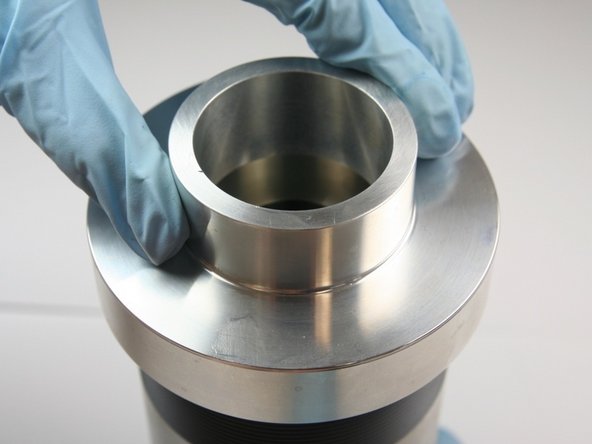

Position the high-pressure cylinder on the seal guide tool.

-

Position the small (stepped) end of the installation tool into the top of the high-pressure cylinder.

-

-

-

Use a rubber mallet to push the internal back-up seal sleeve through the high-pressure cylinder forcing the seal and the hoop out of the other end.

-

Do not remove the sleeve from the high-pressure cylinder.

-

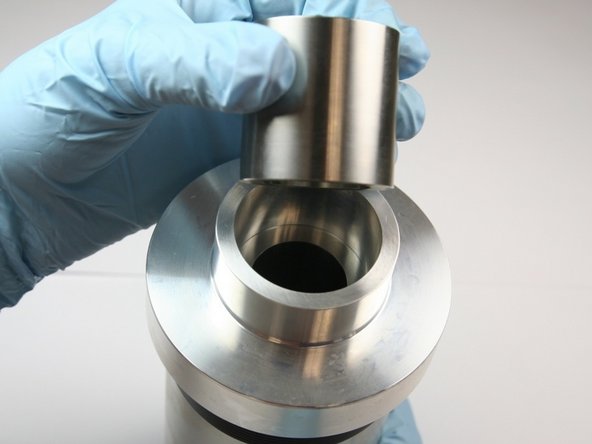

Turn the high-pressure cylinder over so the dynamic end is facing up.

-

Put the non-stepped end of the installation tool in the dynamic side of the high-pressure cylinder, push the other seal out by tapping with a rubber mallet.

-

-

-

Clean the high-pressure cylinder thoroughly after polishing.

-

Visually inspect the high-pressure cylinder bore at both ends.

-

If the inside bore finish is blemished, use scouring pad in both ends of the high-pressure cylinder, to smooth out blemishes, rolling back and forth.

-

-

-

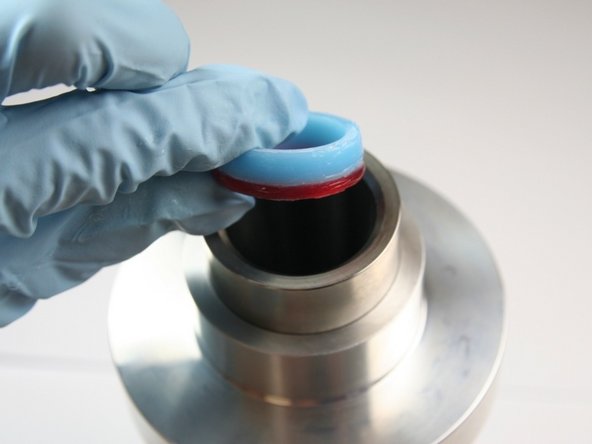

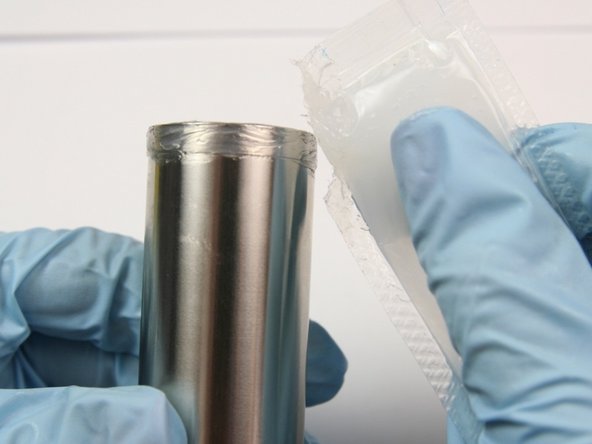

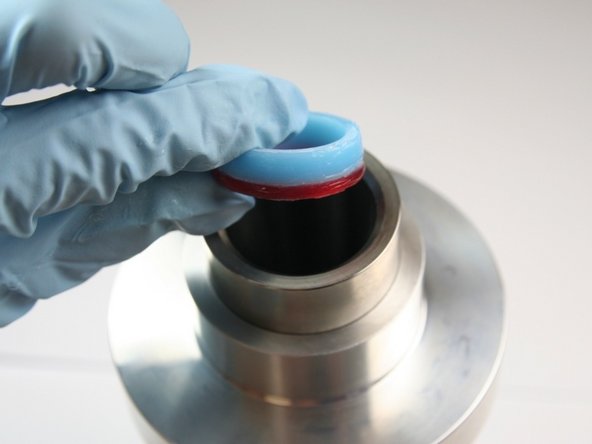

Apply high-vacuum grease to the O-rings.

-

Install all 4 O-rings onto the high-pressure seals.

-

Be sure not to twist the O-rings when installing them onto the high-pressure seals.

-

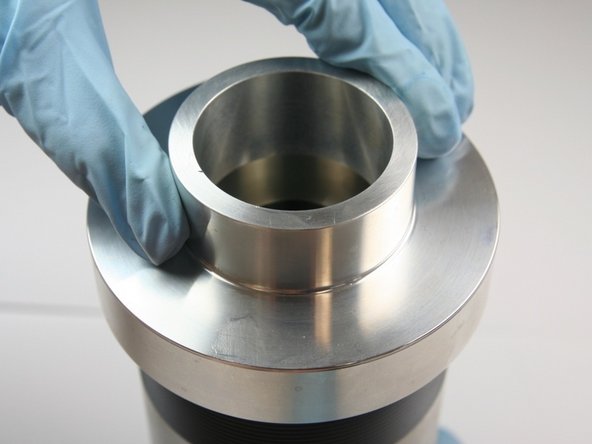

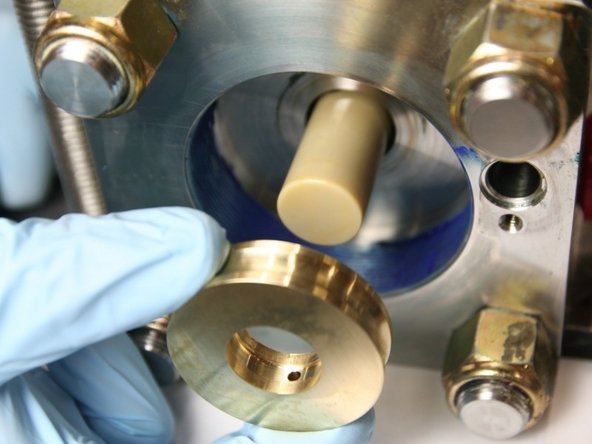

Thread the seal guide tool onto the static end of the high-pressure cylinder.

-

It is helpful to begin with the flat end of the high-pressure cylinder side up.

-

-

-

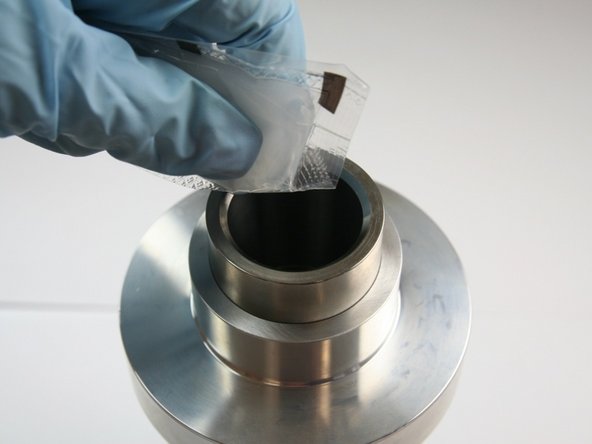

Put the installation sleeve into the sleeve guide with the larger ID (tapered) end up.

-

Lubricate the ID of the Installation sleeve with the high-vacuum grease.

-

Put the high-pressure seal into the sleeve with the O-ring side down.

-

-

-

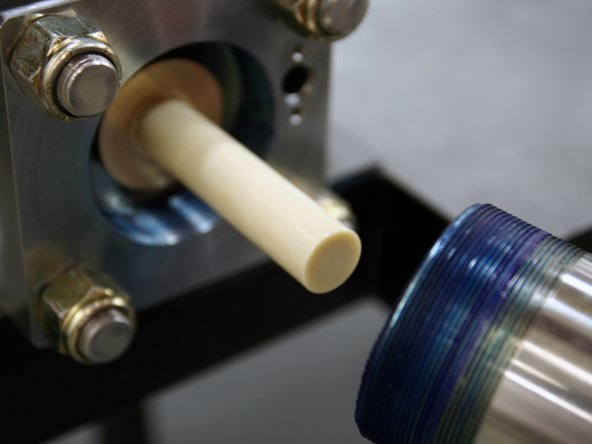

Use the blunt (non-stepped) end of the installation tool to hand press the high-pressure seal into the high-pressure cylinder.

-

Put the hoop into the sleeve with the sharp (tapered) end first.

-

Push the hoop down into the sleeve with the blunt end of the installation tool.

-

-

-

Put the hoop in place by tapping the installation tool in with a rubber mallet until the tool bottoms at the high-pressure cylinder face.

-

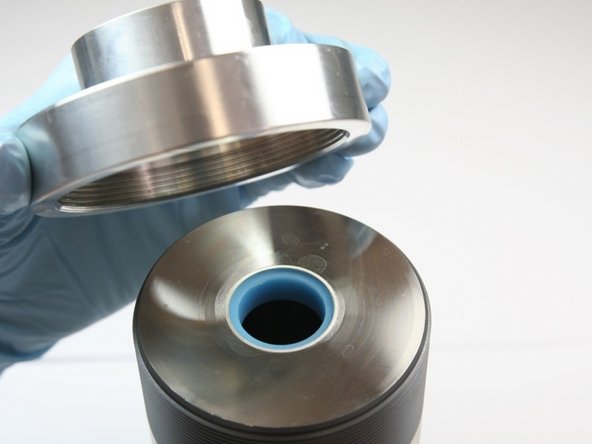

Remove the seal guide tools from the top of the high-pressure cylinder (static side).

-

Apply a light coat of grease to both ends of the back-up seal sleeve.

-

-

-

Put the sleeve into the open end of the high-pressure cylinder and repeat the high-pressure seal installation process.

-

Thread the seal guide tool onto the dynamic side of the high-pressure cylinder.

-

Put the sleeve into the seal guide tool with the tapered end facing up.

-

-

-

Apply a high-vacuum grease to the ID of the sleeve.

-

Put the seal assembly into the sleeve with the O-ring first.

-

Use the blunt (non-stepped) end of the installation tool to hand press the high-pressure seal into the high-pressure cylinder.

-

-

-

Put the hoop into the sleeve with the sharp (tapered) end first.

-

Push the hoop down into the sleeve with the blunt end of the installation tool.

-

Put the hoop in place by tapping the installation tool in with a rubber mallet until the tool bottoms out on the high-pressure cylinder face.

-

-

-

Remove the seal guide tools from the dynamic side of the high-pressure cylinder.

-

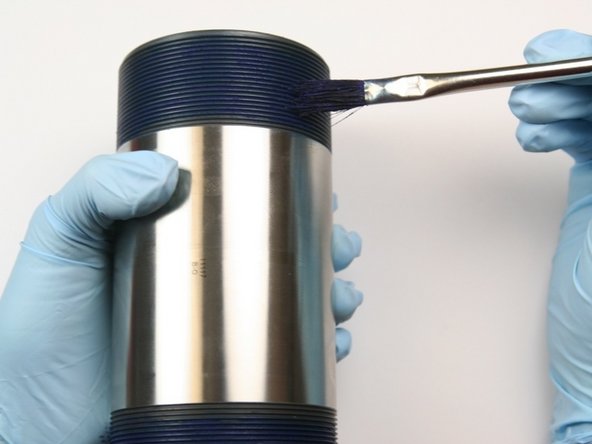

Apply Blue Goop to both threads of the high-pressure cylinder.

-

Remove the old bronze back-up ring from the plunger.

-

Cancel: I did not complete this guide.

12 other people completed this guide.