Introduction

Hypertherm is in no way affiliated with the above mentioned manufacturer

-

-

Always make sure all high-pressure water has been removed from the valve by the following machine manufacturers' safety instructions. Failure to do so can cause severe injury or death.

-

Turn OFF all water pressure to the on/off valve.

-

-

-

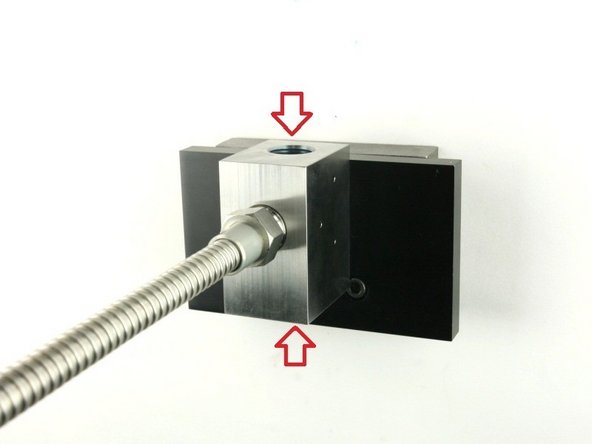

The valve components can be replaced with the valve body mounted to the pump.

-

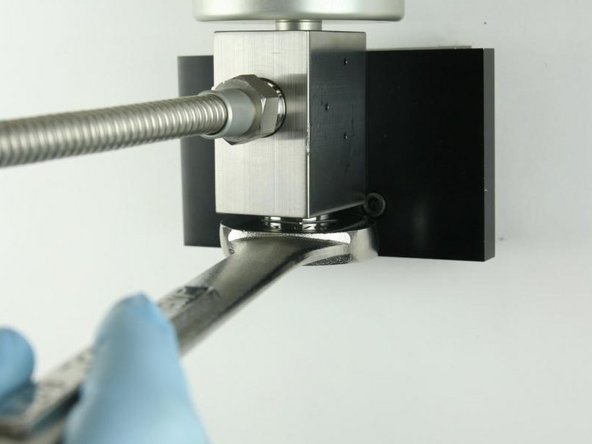

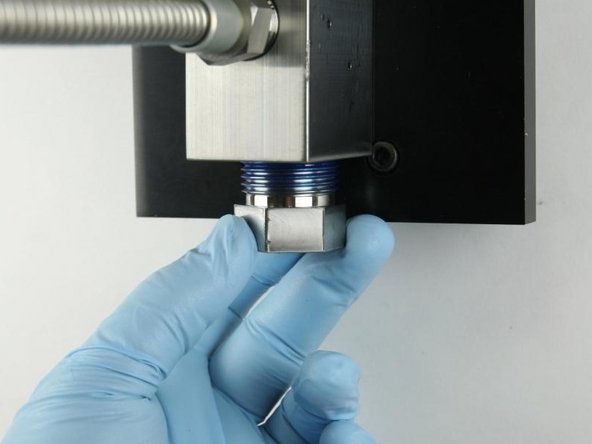

Loosen the high-pressure tubing from the high-pressure gland fitting using a 5/8" and 1" wrench.

-

Unthread the high-pressue tubing from the high-pressure gland fitting.

-

-

-

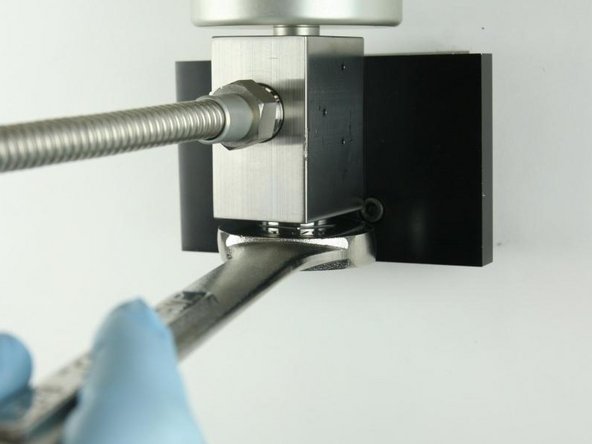

Loosen the high-pressure gland fitting using a 1-1/8" wrench.

-

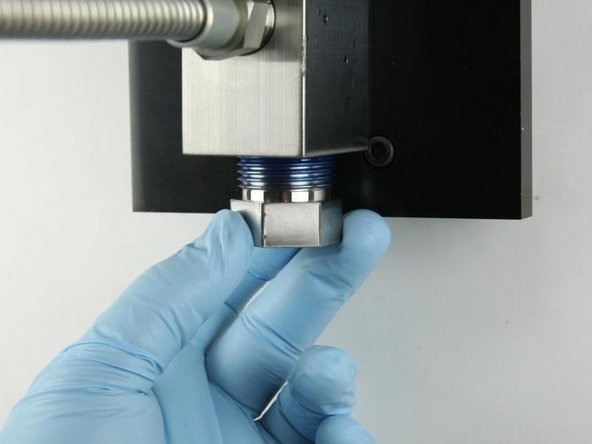

Unthread the high-pressure gland fitting from the valve body.

-

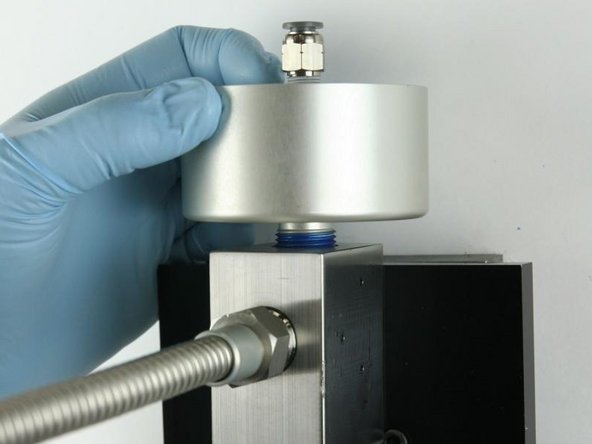

Disconnect the air line from the actuator.

-

-

-

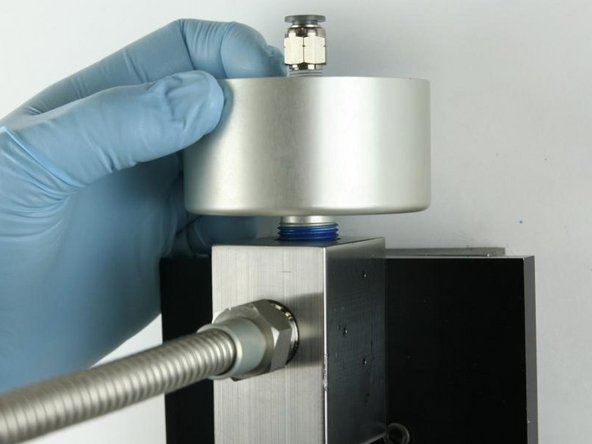

Unthread the actuator from the valve body.

-

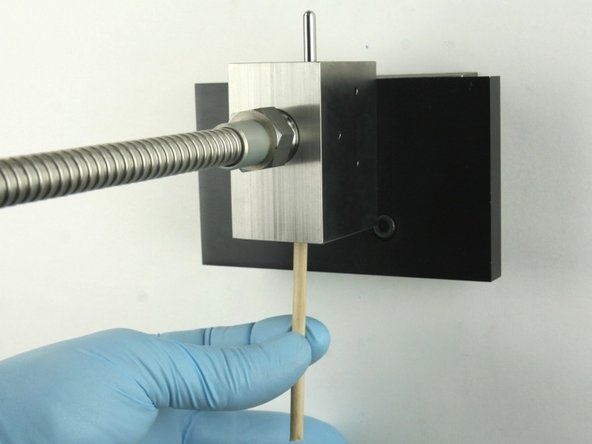

Remove all the valve components from the valve body with the included dowel.

-

Thoroughly clean theinterior of the valve body with isopropyl alcohol or a similar cleaning agent before replacing the components.

-

-

-

Visually inspect the top and bottom of the valve bore for cracks/blemishes. If excessive wear or cracks are visible, replace the valve body.

-

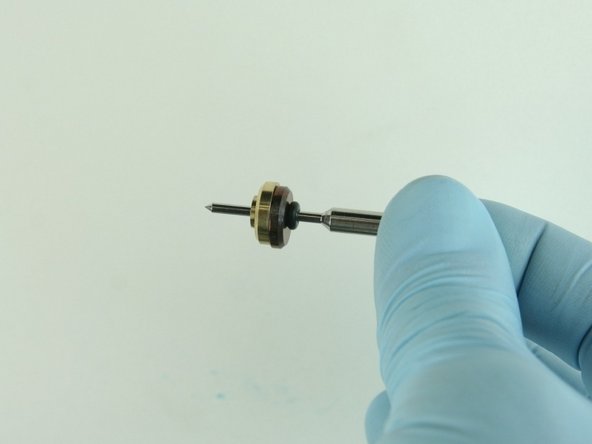

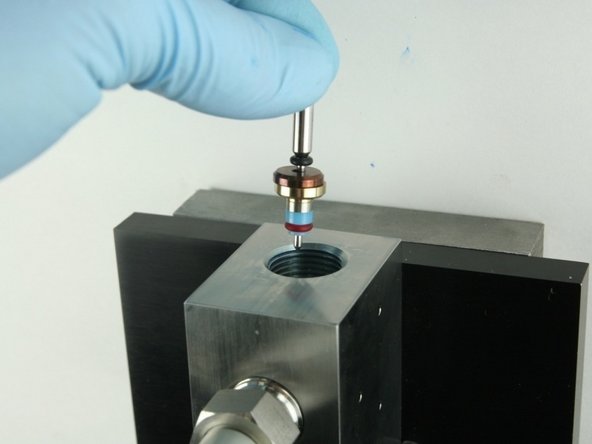

Slide the O-ring on to the point of the valve stem.

-

Slide the stainless steel back-up ring on to the valve stem point with the chamfer side towards the O-ring.

-

-

-

Slide the brass back-up ring on to the valve stem point with the chamfer side away from the stainless steel back-up ring.

-

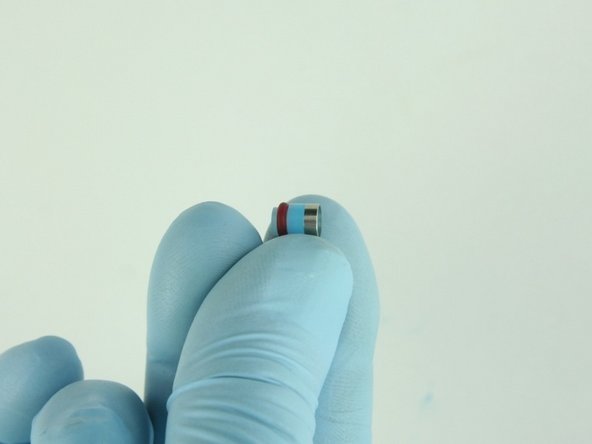

Put the hoop on the high-pressure seal with the sharp edge of the hoop towards the seal.

-

Slide the hoop and the high-pressure valve seal onto the valve stem with the hoop towards the brass back-up ring.

-

-

-

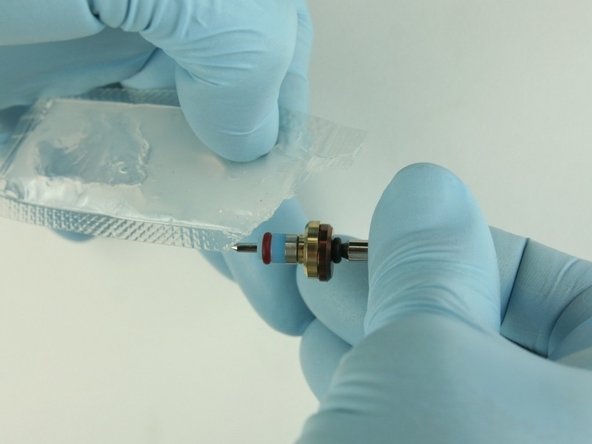

Apply high-pressure lubricant to the outside diameter of the high-pressure valve seal.

-

Put the point of the valve stem into the valve body.

-

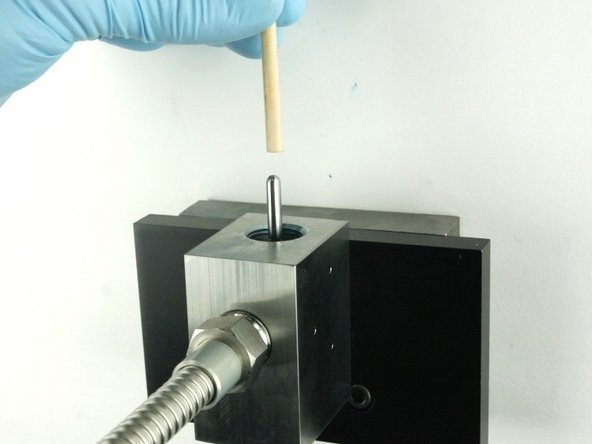

Push the valve stem with the dowel until it bottoms out.

-

-

-

Reconnect the air tube to the actuator.

-

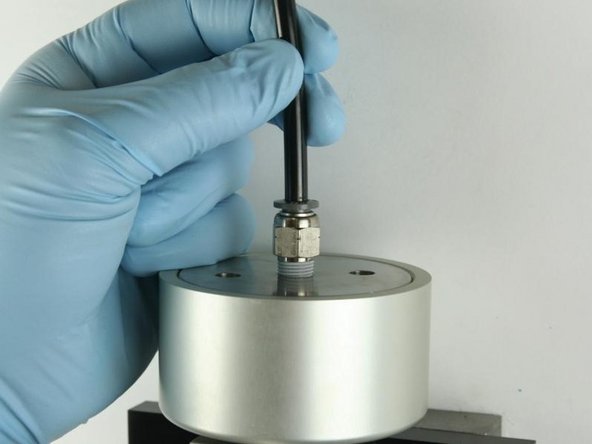

Clean the high-pressure gland fitting of all Blue Goop.

-

Reapply Blue Goop to the threads of the high-pressure gland fitting.

-

-

-

Put the seat into the top of the high-pressure gland fitting with the flat side towards the gland fitting.

-

Apply Blue Goop to the top of the seat.

-

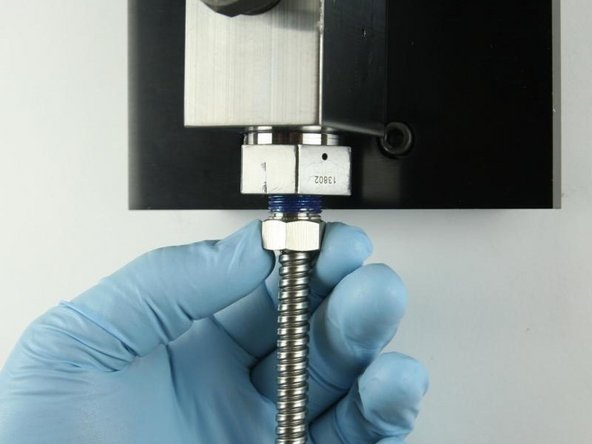

Thread the high-pressure gland fitting into the bottom of the valve body.

-

-

-

Tighten the high-pressure gland fitting using a 1-1/8" wrench.

-

Clean the high-pressure tubing threads and cone of all Blue Goop with isopropyl alcohol or a similar cleaning agent.

-

Reapply Blue Goop to the high-pressure tubing threads and cone.

-

-

-

Thread in the high-pressure tubing to the bottom of the high-pressure gland fitting.

-

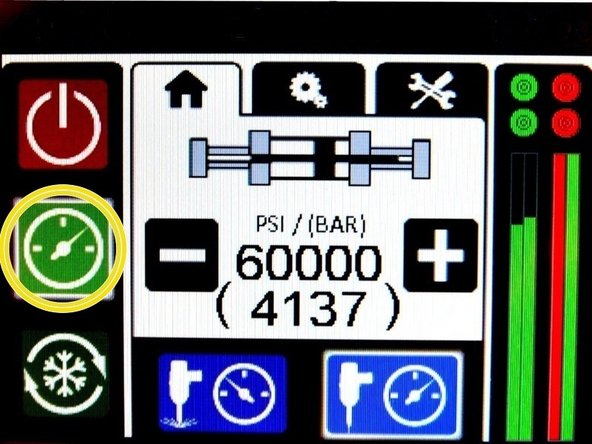

Apply water pressure to the valve assembly to verify there are no leaks.

-

Re-install the cutting head and continue the cutting process.

-

-

-

Re-install the cutting head and continue the cutting process.

-