Introduction

Hypertherm is in no way affiliated with the above mentioned manufacturer

-

-

Use the small stepped end of the installation tool to push the internal back-up sleeve through the cylinder forcing the seal and hoop out of the other end of the high-pressure cylinder.

-

Turn over the high-pressure cylinder and repeat this process.

-

Thoroughly clean the high-pressure cylinder with isopropyl alcohol or a similar cleaning agent.

-

-

-

Visually inspect the bore of the high-pressure cylinder and check for cracks/blemishes.

-

Use Scotch Brite on both ends of the high-pressure cylinder to smooth out blemishes.

-

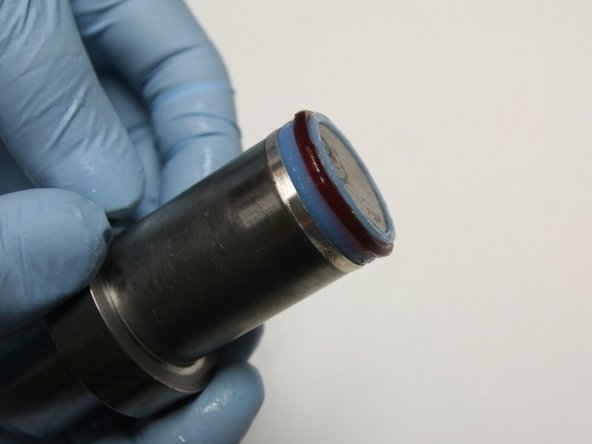

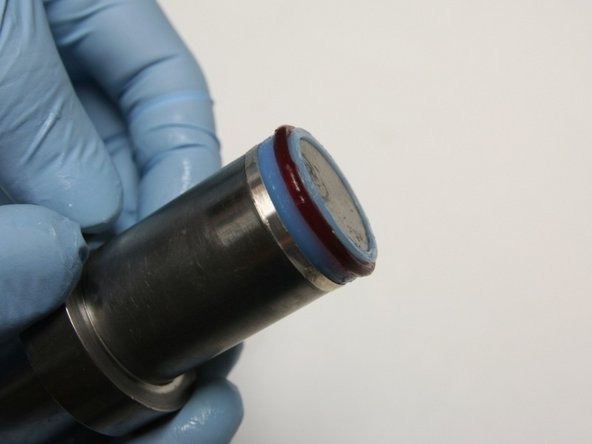

Put the seal guide tool onto the one end of the high-pressure cylinder.

-

The seal guide should spin on the high-pressure cylinder when installed correctly.

-

-

-

Put the installation sleeve into the sleeve guide with the larger ID, with the tapered end, up.

-

Apply high vacuum grease to the O-ring.

-

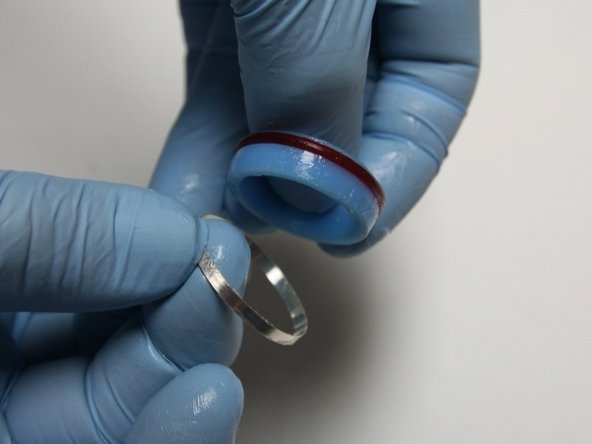

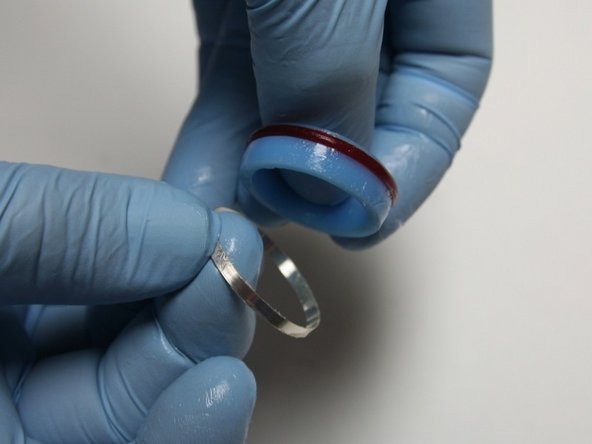

Put the O-ring on the seal.

-

-

-

Secure the hoop in place by tapping the installation tool with a rubber mallet until the tool bottoms out on the guide.

-

Apply high vacuum grease to both ends of the spacer tube.

-

Remove the tools from the finished end of the high-pressure cylinder, turn the high-pressure cylinder over, and insert the spacer tube into the bore.

-

-

-

Put the seal guide tool onto the end of the high-pressure cylinder and the seal guide should spin on the high-pressure cylinder when installed correctly.

-

Put the installation sleeve into the sleeve guide with the larger ID, with the tapered end, up.

-

Apply high vacuum grease to the O-ring.

-

-

-

Put the O-ring onto the high-pressure seal.

-

Put the hoop with the sharp (tapered) end down onto the back of the seal.

-

Put the seal and hoop onto the bigger stepped side of the installation tool.

-

-

-

Put the installation tool with the hoop and seal into the sleeve.

-

Secure the hoop in place by tapping the installation tool with a rubber mallet until the tool bottoms out on the guide.

-

Proceed to the installation of the cylinder on the intensifier.

-

Cancel: I did not complete this guide.

3 other people completed this guide.