Parts

- Major Swivel Repair Kit #12609

- Swivel Bearing Back-up #13642 (included in kit)

- Swivel Shaft #13633 (Included in kit)

- Thrust Bearing #13644 (included in kit)

- Thrust Bearing Washer #13645 (included in kit) × 2

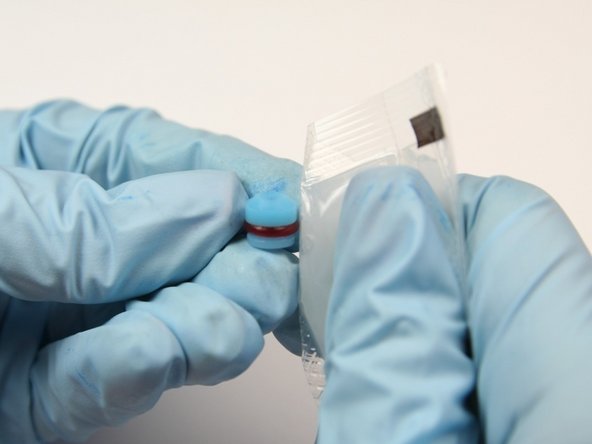

- Seal, 1/4" Swivel #12867 (included in kit)

- O-ring, "Red" #12662-008 (included in kit)

- O-ring #11679-022 (included in kit)

- High-Vacuum Grease #11447 (included in kit)

- Wiper, .250 ID X .500 OD 70D #13651

- Swivel Bearing #13646

- Swivel Housing, Bearing Half, 1/4" #13650

- Swivel Housing, Seal Half #13641

- Swivel Collar #13643

- Blue Goop #11111

- Lithium Grease

- Isopropyl Alcohol

-

-

Loosen the high-pressure gland from the swivel collar with 5/8" and 3/4" wrench.

-

Unthread the high-pressure gland from the swivel collar.

-

Clean the high-pressure gland and the high-pressure tubing cone with isopropyl alcohol or a similar cleaning agent.

-

-

-

Remove the swivel collar from the swivel housing.

-

Loosen the high-pressure gland from the coupling with 1-1/16" and 5/8" wrench.

-

Unthread the high-pressure gland at the top of the swivel shaft from the coupling.

-

-

-

Uthread the high-pressure collar from the threads of the swivel shaft.

-

Remove the high-pressure gland and the collet from the swivel shaft.

-

Clean the high-pressure gland of all Blue Goop with isopropyl alcohol.

-

-

-

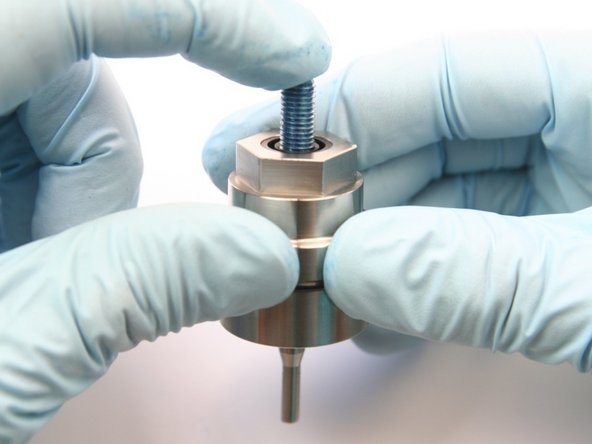

Use two 3/4" wrenches to separate the bearing half and the seal half of the swivel housing.

-

Unthread the bearing half from the seal half of the swivel housing.

-

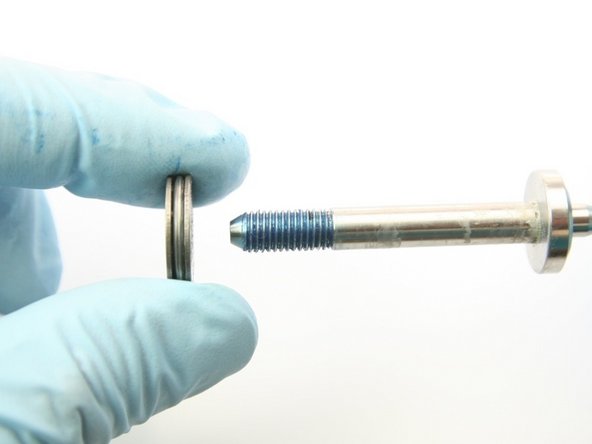

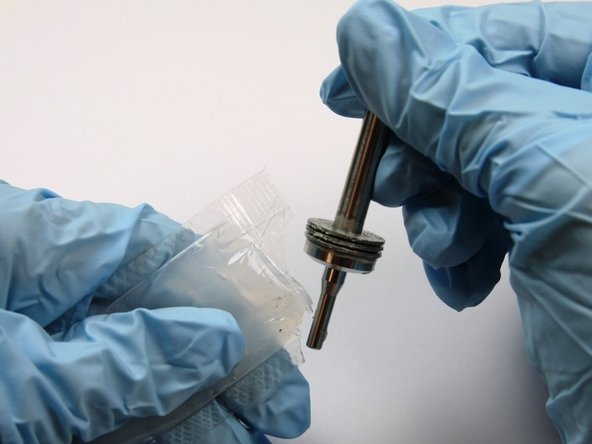

Remove the swivel shaft from the bearing half of the swivel housing by pushing down through the wiper.

-

When removing the swivel shaft, the top thrust washer could stick to the inside top of the bearing half.

-

-

-

Remove the thrust washers and the thrust bearing from the swivel shaft.

-

Remove the bearing back-up from the seal half of the swivel housing.

-

Remove the high-pressure seal assembly from the seal half of the swivel housing with a pick.

-

Be sure to not scratch the ID of the swivel housing with the pick.

-

-

-

Clean the seal half of the swivel housing of all Blue Goop with isopropyl alcohol or a similar cleaning agent.

-

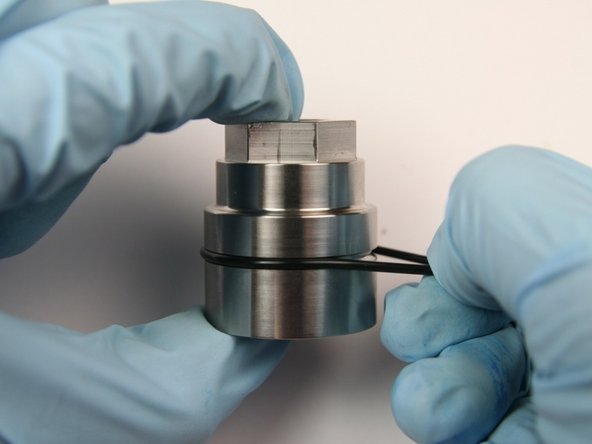

Remove the O-ring from the bearing half of the swivel housing.

-

Remove the wiper from the top of the bearing half of the swivel housing with a pick.

-

-

-

Remove the swivel bearing from the bearing half of the swivel housing by pushing a .300-.360 gauge pin through the bearing half.

-

Clean the swivel bearing half of the swivel housing with isopropyl alcohol or a similar cleaning agent.

-

Apply a layer of high vacuum grease into the cavity of the seal half of the swivel housing.

-

-

-

Put the bearing back-up into the seal half of the swivel housing on the top of the high-pressure seal with a .300-.360 gauge pin until it bottoms out.

-

Be sure that the swivel bearing is flush with the bottom of the cavity of the bearing half of the swivel housing.

-

Apply lithium grease to the shelf of the new swivel shaft from the kit.

-

-

-

Put the first thrust washer from the kit onto the swivel shaft.

-

Apply lithium grease to the top of the first thrust washer.

-

Put the thrust bearing onto the swivel shaft.

-

-

-

Apply lithium grease to the top of the thrust bearing.

-

Put the second thrust washer onto the swivel shaft.

-

Apply lithium grease to the top of the thrust washer.

-

-

-

Apply high vacuum grease to the short end of the swivel shaft.

-

Put the back-up bearing into the top of the seal half of the swivel housing.

-

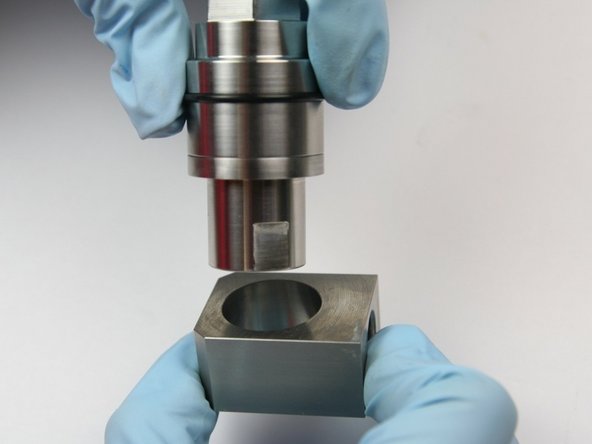

Put the short end of the swivel shaft into the back-up bearing until it bottoms out.

-

-

-

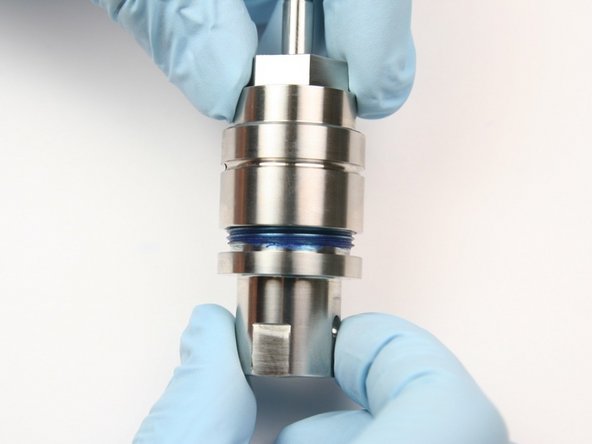

Thread the bearing half of the swivel housing onto the seal half of the swivel housing.

-

Tighten both seal half and bearing half of swivel housing using two 3/4" wrench.

-

Put the wiper over the swivel shaft and down into the top of the bearing half of the swivel housing.

-

-

-

Put the O-ring over the swivel shaft and into the groove of the swivel body.

-

Put the swivel housing into the swivel collar with the high-pressure inlet hole facing through the collar hole.

-

Apply Blue Goop to the high-pressure gland threads.

-

-

-

Thread the high-pressure gland into the swivel collar.

-

Tighten the high-pressure gland with 3/4" and 5/8" wrench.

-

Apply Blue Goop to the high-pressure gland threads.

-

-

-

Place the collet with the tapered side down into the high-pressure gland.

-

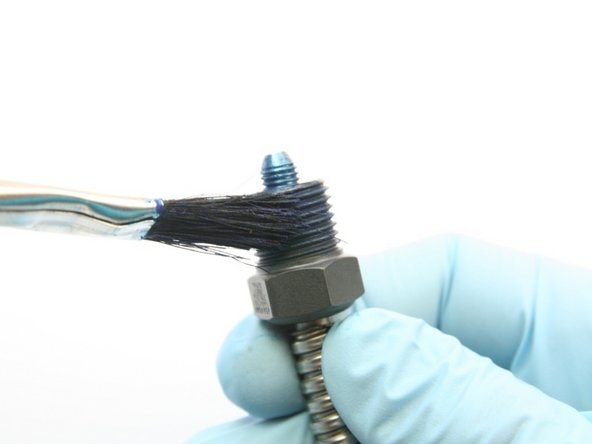

Apply Blue Goop to the swivel shaft threads.

-

Slide the high-pressure gland with the collet onto the swivel shaft.

-

-

-

Thread on the collar to the bottom of the threads of the swivel shaft.

-

Thread the high-pressure gland into the coupler.

-

Tighten the high-pressure gland into the coupler using 1-1/16" and 5/8" wrench.

-