Introduction

Hypertherm is in no way affiliated with the above mentioned manufacturer

Tools

Parts

- Pneumatic Valve Repair Kit #14324

- Seat #11099 (included in kit)

- Bronze Back-up Ring #14314 (included in kit)

- Valve Stem #14310 (included in kit)

- High-Pressure Seal Assembly #14322 (included in kit)

- High-Vacuum Grease #11447 (included in kit)

- Actuator #13243

- Valve Body #11320

- High-Pressure Gland Fitting #12347

- Isopropyl Alcohol

- Blue Goop #11111

- Lithium Grease

-

-

Always make sure all high-pressure water has been removed from the valve by the following machine manufacturers' safety instructions. Failure to do so can cause severe injury or death.

-

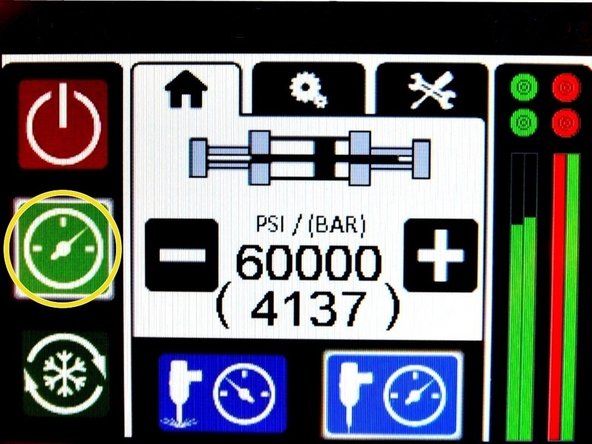

Turn OFF all water pressure to the on/off valve.

-

The valve components can be replaced with the valve body mounted to pump.

-

-

-

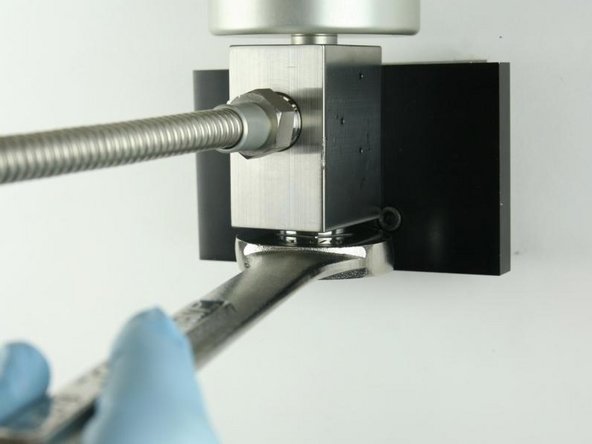

Loosen the high-pressure tubing from the high-pressure gland fitting using a 5/8" and 1" wrench.

-

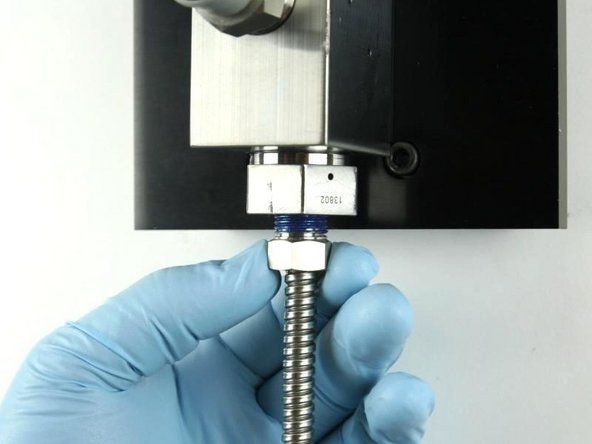

Unthread the high-pressure tubing from the high-pressure gland fitting.

-

Loosen the high-pressure gland fitting using a 1" wrench.

-

-

-

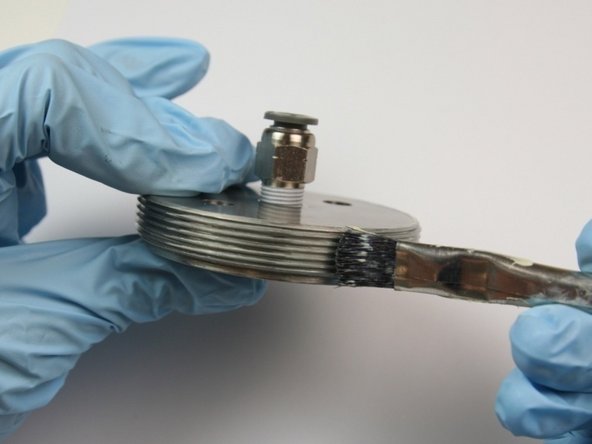

Clean the actuator threads of all Blue Goop with isopropyl alcohol or a similar cleaning agent.

-

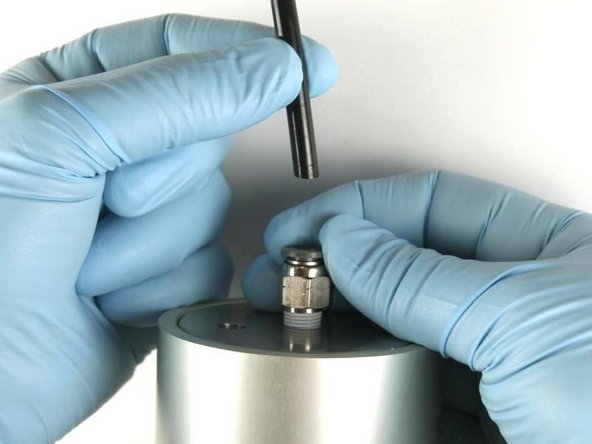

Loosen the cap to the actuator with a spanner wrench and a 3/4" breaker bar.

-

Put the actuator housing in the soft-jaw vise if necessary.

-

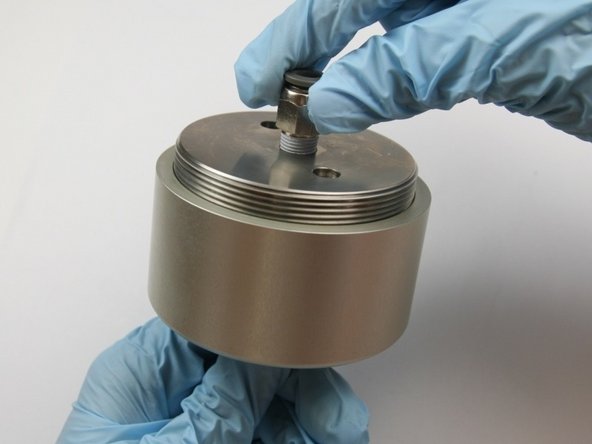

Unthread the cap from the actuator.

-

-

-

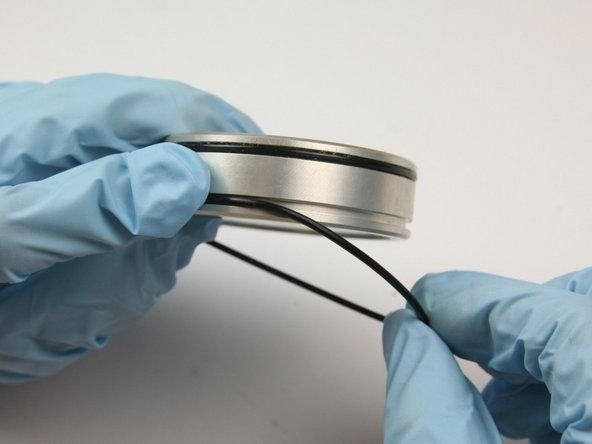

Remove the largest O-ring from the actuator housing.

-

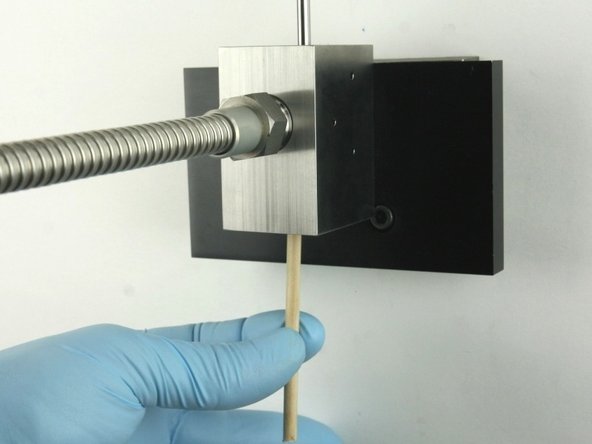

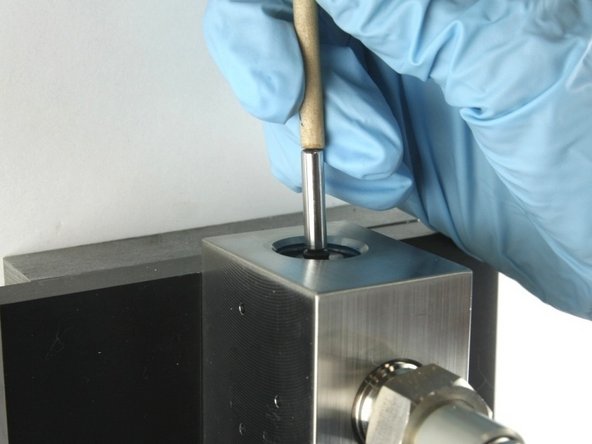

Push the dowel (included in the kit) through the hole of the threaded nipple onto the actuator housing to remove the piston.

-

Remove the first O-ring from the piston groove.

-

-

-

Remove the second O-ring from the piston groove.

-

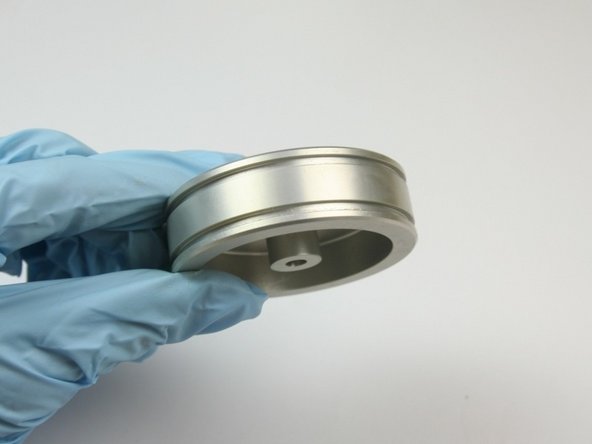

Visually inspect the actuator piston for cracks/wear.

-

Clean the actuator cap of all lithium grease.

-

-

-

Clean the piston of all high vacuum lubricant.

-

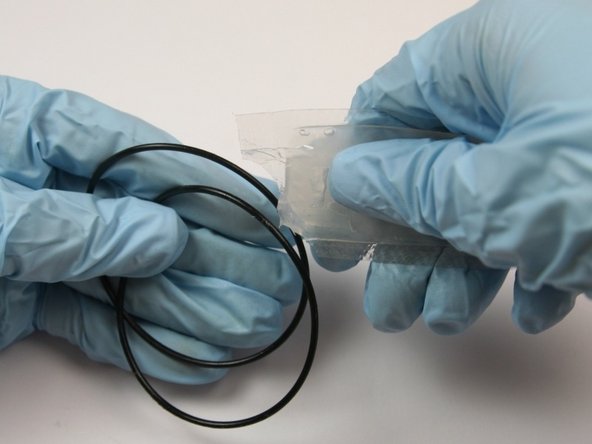

Apply high vacuum grease to the two smallest O-rings from the kit.

-

Put one O-ring from the kit onto the groove of the piston.

-

-

-

Put the other O-ring from the kit onto the second groove of the piston.

-

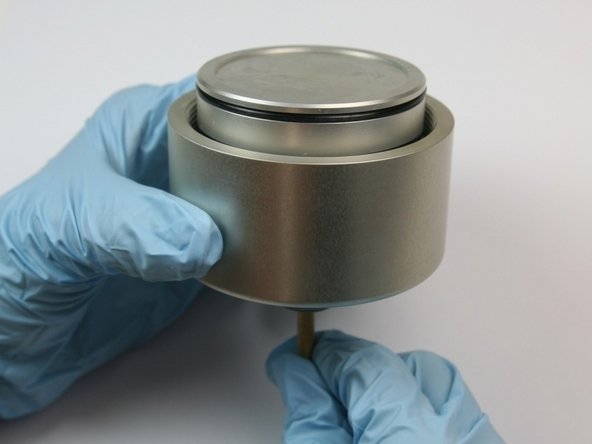

Push the piston into the actuator housing with the flat side of the piston up until it bottoms out.

-

Apply high vacuum grease to the biggest O-ring from the kit.

-

-

-

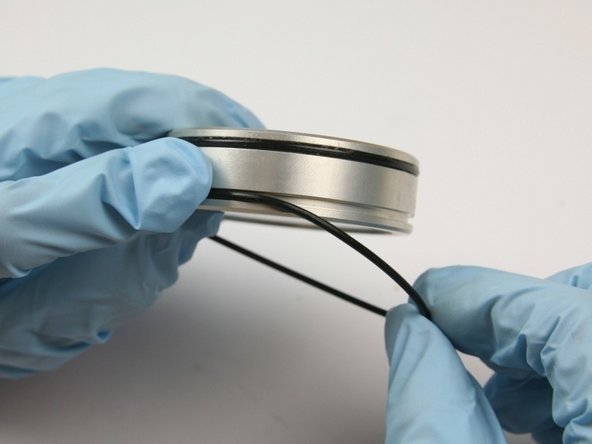

Put the O-ring into the groove on the inside of the actuator housing.

-

Apply lithium grease to the threads of the actuator cap.

-

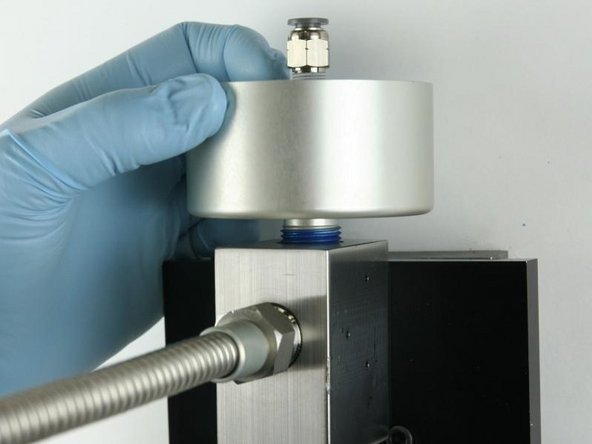

Thread the actuator cap into the actuator housing.

-

-

-

Tighten the actuator cap to the actuator housing with a spanner wrench and a 3/4" breaker bar.

-

Remove all the valve components from the valve body with the included dowel.

-

Thoroughly clean the interior of the valve body with the isopropyl alcohol or a similar cleaning agent before replacing the components.

-

-

-

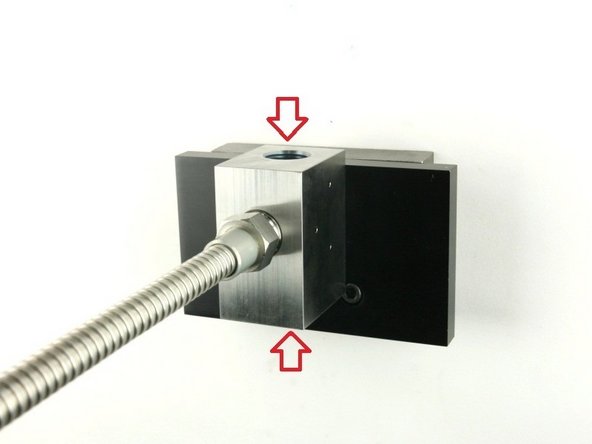

Visually inspect the top and bottom of the valve bore for cracks/blemishes. If excessive wear or cracks are visible, replace the valve body.

-

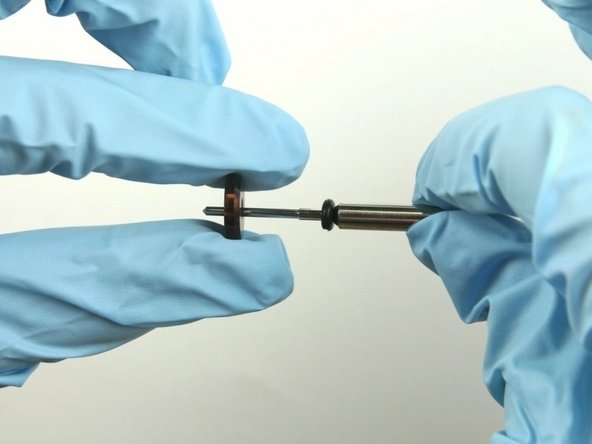

Slide the O-ring on to the point of the valve stem.

-

Slide the stainless steel back-up ring on to the valve stem point with the chamfer side towards the O-ring.

-

-

-

Slide the bronze back-up ring on to the valve stem point with the chamfer side away from stainless steel back-up ring.

-

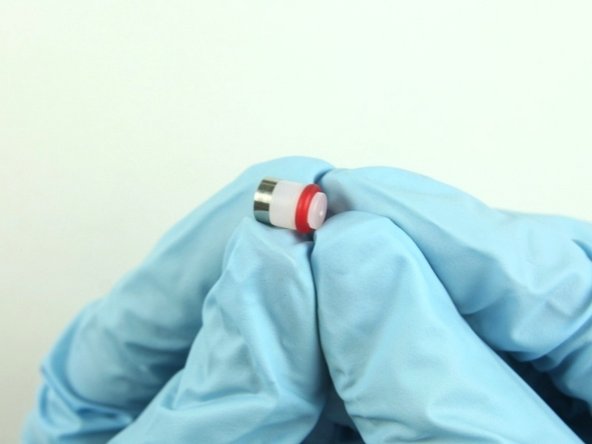

Put the hoop on the high-pressure seal with the sharp edge of the hoop towards the seal.

-

Slide the hoop and the high-pressure valve seal on to the valve stem with the hoop towards the brass back-up ring.

-

-

-

Apply high vacuum grease to the outside diameter of the high-pressure valve seal.

-

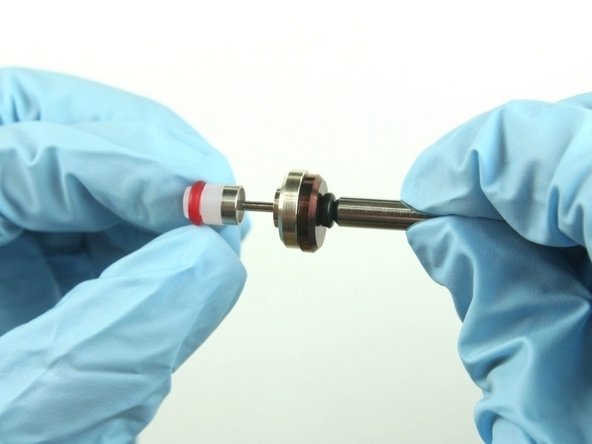

Put the point of the valve stem into the valve body.

-

Push the valve stem with the dowel until it bottoms out.

-

-

-

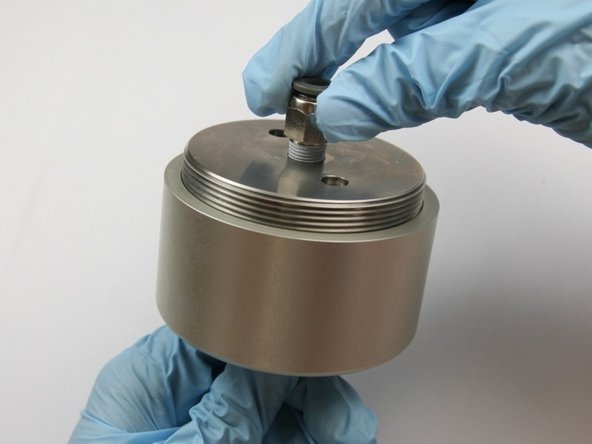

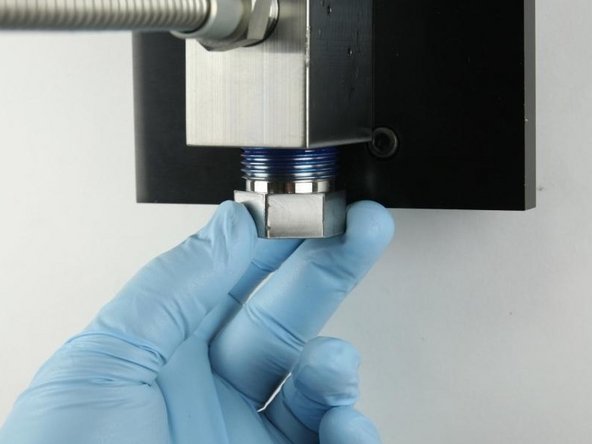

Clean the high-pressure gland fitting of all Blue Goop.

-

Reapply Blue Goop to the threads and to the top of the high-pressure gland fitting.

-

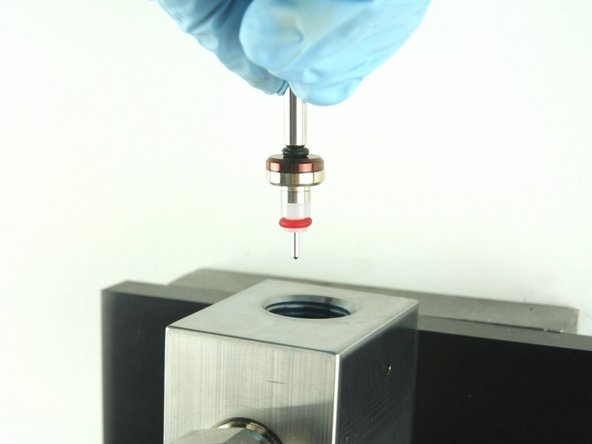

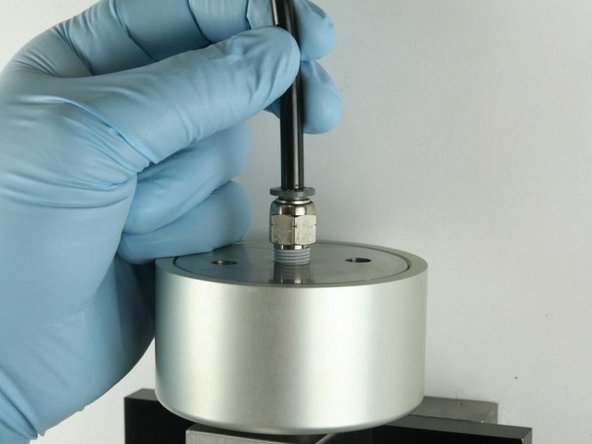

Put the seat into the top of the high-pressure gland fitting with the flat side towards the gland fitting.

-

-

-

Apply Blue Goop to the top of the seat.

-

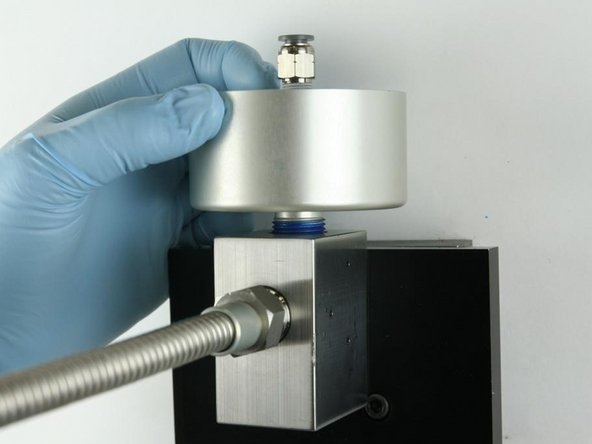

Thread the high-pressure gland fitting into the bottom of the valve body.

-

Tighten the high-pressure gland fitting using a 1-1/8" wrench.

-

-

-

Clean the high-pressure tubing threads and cone of all Blue Goop with isopropyl alcohol or a similar cleaning agent.

-

Reapply Blue Goop to the high pressure tubing threads and cone.

-

Thread in the high-pressure tubing to the bottom of the high-pressure gland fitting.

-

-

-

Tighten the high-pressure tubing to the high-pressure gland fitting using a 5/8" and 1" wrench.

-

Apply water pressure to the valve assembly to verify there are no leaks.

-

Re-install the cutting head and continue the cutting process.

-

Cancel: I did not complete this guide.

2 other people completed this guide.